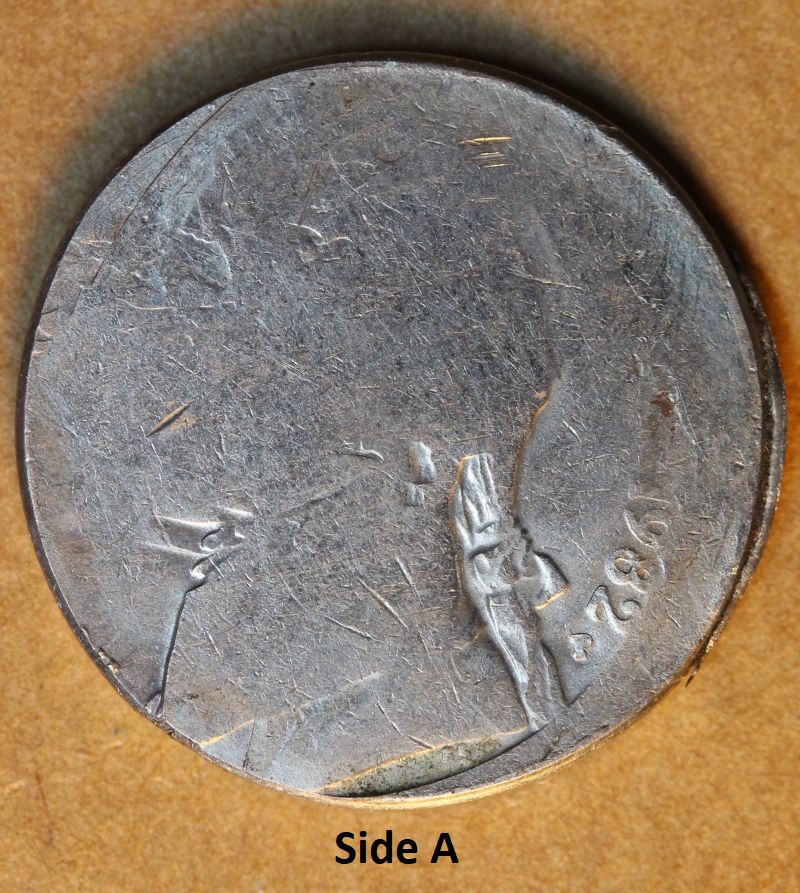

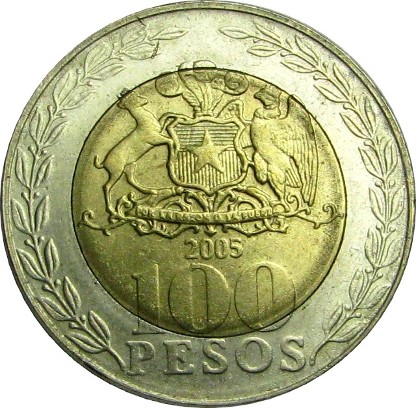

PART VI. Striking Errors:

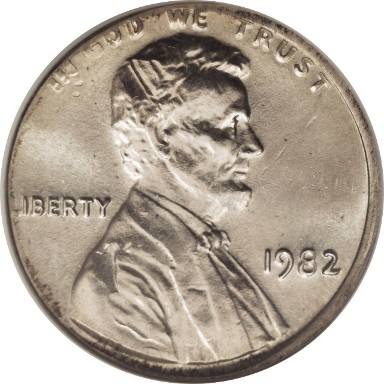

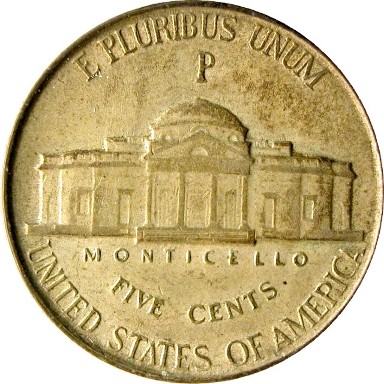

Bi-metallic Errors:

Bi-metallic design struck on wrong bi-metallic

planchet

Note: Weight of this coin is 7.20 g, versus the normal weight of 7.58 g. The ring and core colors are opposite of a normal 100 pesos bi-metallic planchet & duller. The diameter & thickness are normal.

Note: Specifications for a normal 100 pesos bi-metallic planchet are listed below.

Normal 100 pesos bi-metallic planchet specifications are: 100 Pesos Ring Composition 92% Copper, 2% Nickel, 6% Zinc.

100 Pesos Core Composition 70% Copper,, 15% Nickel, 15% Zinc.

Weight (grams) : Planchet (ring & core) – 7.58g

Separately: Ring – 3.38 g, Core – 4.20 g

Diameter 23.5 mm

Thickness 2.0 mm