Part V. Planchet Errors:

Subsurface Corrosion

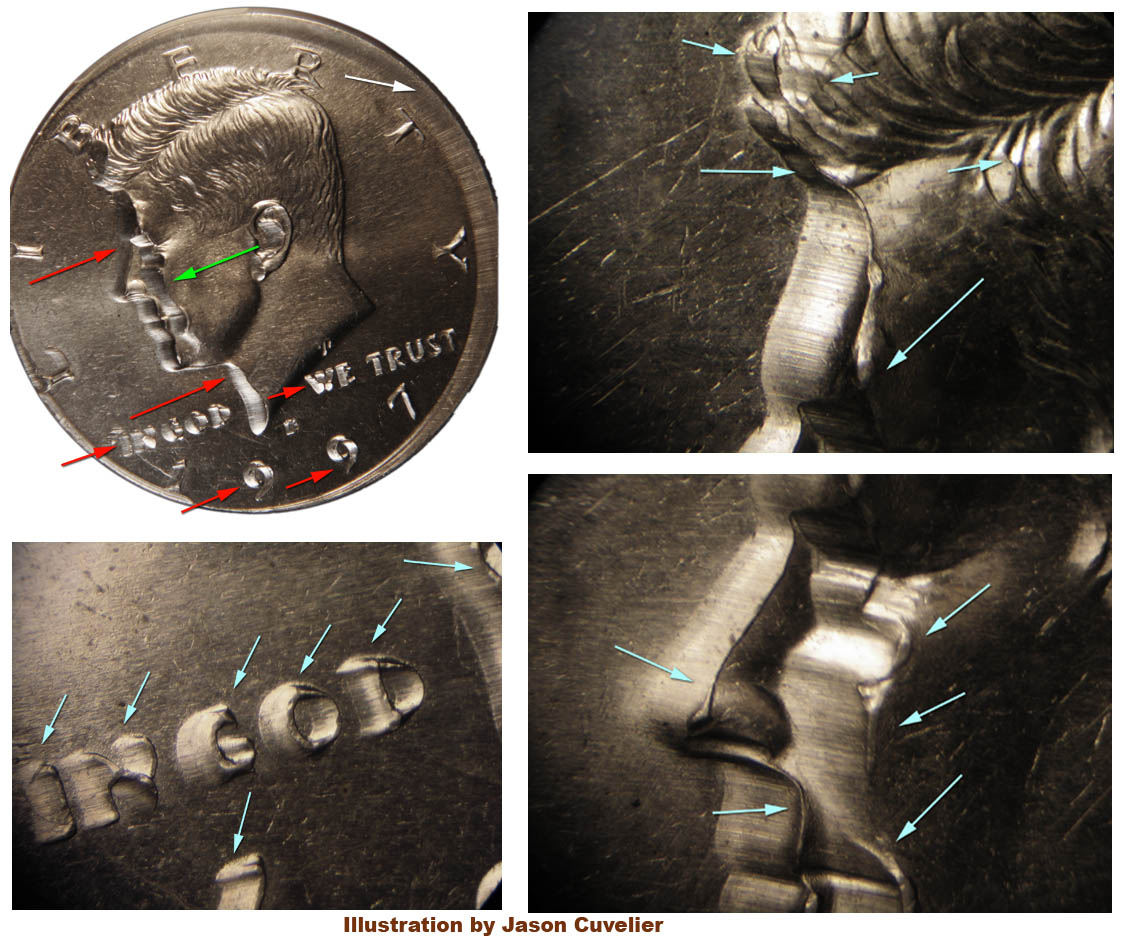

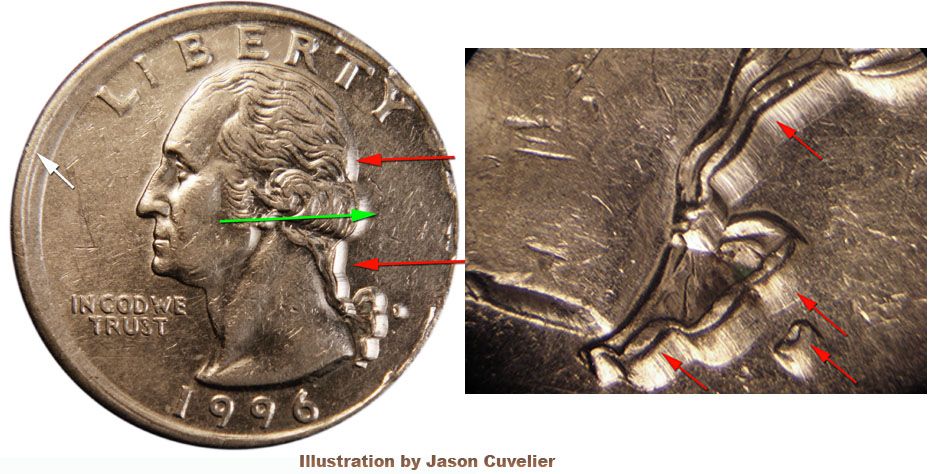

Definition: Corrosion that occurs beneath the surface due to the presence of contaminants that react with the surrounding metal. Subsurface corrosion produces an expanding lens of spongy rot that forces up the overlying metal into various shapes. These solid elevations can be round, oblong, or elongated. If the roof ruptures, the exposed rot can fall out or collapse, leaving a crater.

Subsurface corrosion can occur in solid-metal coins, appearing most frequently in aluminum coins.

Subsurface corrosion occurs even more frequently in plated coins, when contaminants get trapped between the plating and the core. For example, in copper-plated zinc cents, domes of solid rot will push up the overlying copper plating. These domes can resemble plating blisters, but their etiology is entirely different. Plating blisters are hollow and are produced by expanding gas in the immediate aftermath of the strike.

Although subsurface corrosion is technically a planchet error, it is undesirable and has no value.

This solid-aluminum 1969 South Korea 1 won shows the effects of subsurface corrosion on its obverse face. A long, thin ridge is the dominant feature. Although it resembles a die crack, the fact that the design continues across it shows that this is not the case. Accessory patches of corrosion are found elsewhere on the obverse. Some of the smaller pimples have ruptured, exposing pale, milky rot.