Part VI. Striking Errors:

Skidding Die Errors:

Skidding Misalignments

Definition: A horizontal misalignment that occurs as the hammer die is penetrating the planchet.

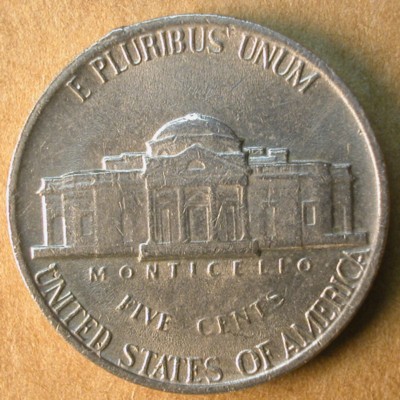

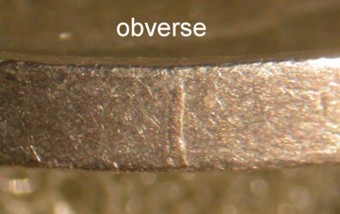

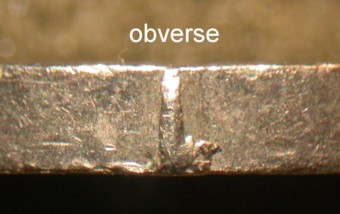

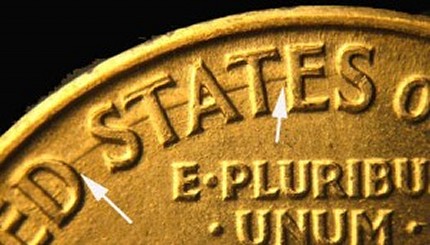

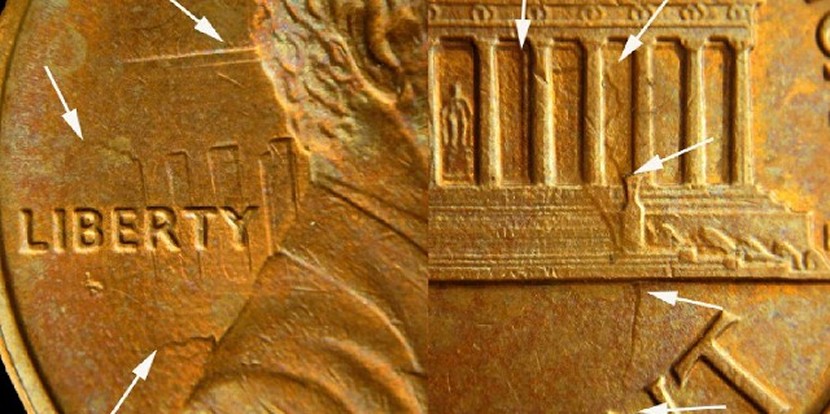

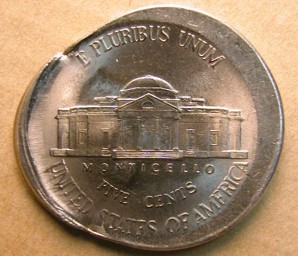

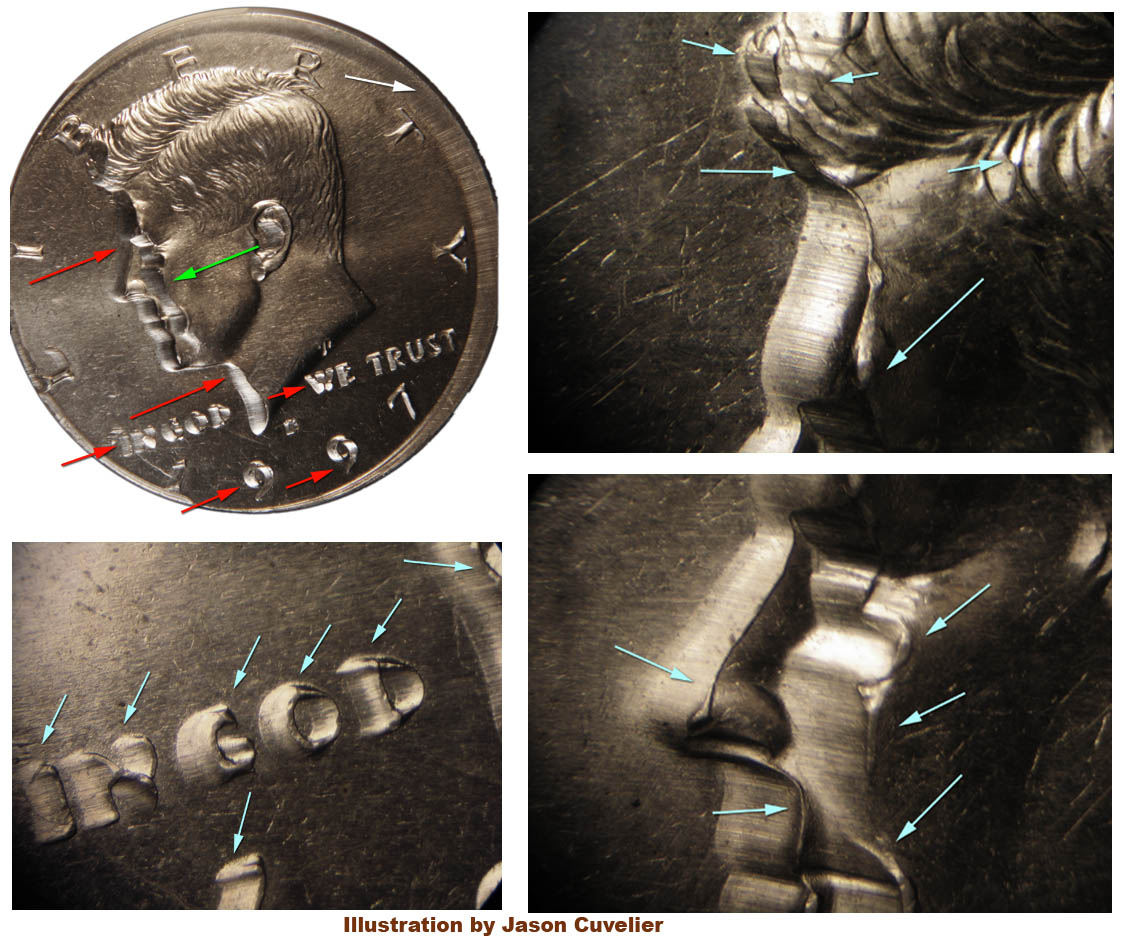

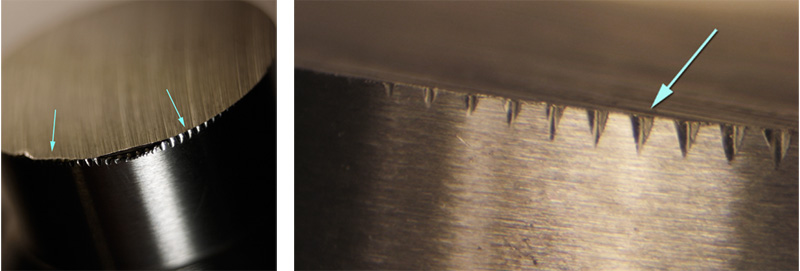

These two 1999-D nickels were struck in-collar by the same wildly oscillating hammer (obverse) die. In each instance the hammer die was perfectly centered when it made initial contact with the planchet. In our first specimen, the hammer die shifted to the left as it was sinking down into the planchet. This left the coin with a featureless crescent on the right side that displays scouring marks in the form of transverse (crosswise) striations. The hammer die finished its downstroke in a misaligned position. After it reached its lowest point, the hammer die shifted to the right, smearing the newly-struck design and piling the relocated metal into a series of ridges. This would be characterized as a case of slide doubling (a form of machine doubling).

In our second specimen, the hammer die shifted to the right as it was sinking down into the planchet. This left the coin with a featureless crescent on the left side that displays the characteristic transverse striations. The hammer die finished its descent in a misaligned position. After reaching the lowest point of its downstroke, the hammer die shifted to the left, smearing the newly-struck design. Every known skidding misalignment shows slide doubling in the opposite direction.