Alloy errors

-

- Improper alloy mix (CW 12/27/11, 1/30/23, 4/3/23)

- Poorly mixed alloy

- Incorrect proportions of metals

- In conjunction with rolled-thick errors (1941 cents, mainly) (CW 10/15/12)

- Gas Bubbles (CW 11/19/12)

- Intact (“occluded”)

- Ruptured

- Slag inclusions (ES May/June 2006)

- Intrinsic metallic inclusions (ES Sept/Oct 2006; CW 12/27/10, 12/27/11, 7/21/14)

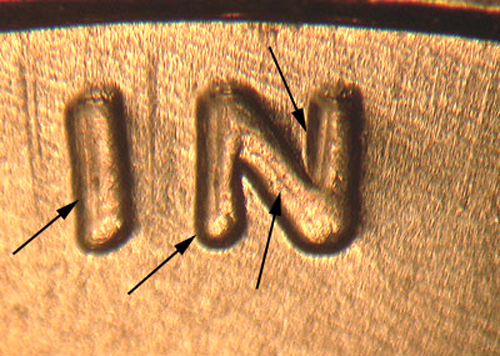

- Lamination errors

- Loss before strike

- Loss after strike

- Lamination cracks

- Retained laminations

- Folded-over before strike (CW 10/22/12)

- Internally split clad layer (CW 10/22/12, 6/26/17)

- Split planchets

- Before strike (CW 8/2/10)

- After strike

- Wrong Denomination / Off-metal

- Struck with another planchet on top or beneath

- Split core (clad coins)

- Clamshell split (CW 1/28/13)

- Clamshell folded over before strike (CW 10/22/12, 1/23/13)

- Hemi-split planchets (CW 10/9/23)

- Copper-and-zinc composite “shells” (ES May/June 2001)

- Split-after-strike (N.B. these are probably all detached cap bottoms)

- Cracked planchets

- Broken planchets / coins (CW 3/14/11, 9/18/23)

- Before strike

- After strike

- Brittle coins (cross-classified with annealing errors)

- Radial planchet splits (when struck out-of-collar)

- Delayed radial stress splits (CW 5/2/22)

- Planchet cohesion errors (crumbling planchets) (CW 11/22/21)

- Ragged clips (CW 2/29/16)

- Ragged notch

- Ragged perforations (“blowholes”)

- Fissures — ragged and smooth

- Stress-induced surface irregularities (CW 4/24/17)

- Rolling-Induced Fissures

- Improper alloy mix (CW 12/27/11, 1/30/23, 4/3/23)

Subsurface Corrosion (CW 12/21/15)

-

- Plated coins

- Copper-plated zinc cents

- Solid coins

- Plated coins

Rolling Mill Errors

-

- Rolled-thick planchets

- Rolled-thin planchets (CW 8/2/10, 7/16/18)

- Tapered planchets (CW 12/20/10, 12/28/15)

- On clad coins (clad layer absent) (CW 4/27/15)

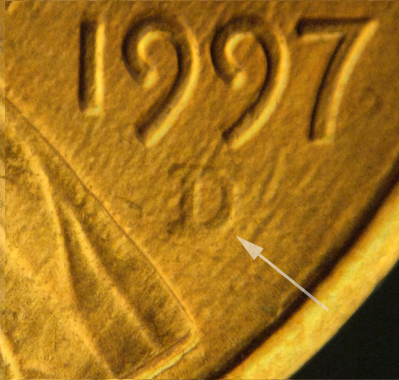

- Rolling indentations (ES Jan/Feb 2000; CW 2/7/11)

- Rolled-in scrap (ES May/June 2006; CW 2/7/11)

- Bristles from descaling brush (CW 3/10/03)

- Roller marks (CW 10/13/14)

- Rolled-in patterns and textures

- Rolled-in cloth pattern (CW 3/21/16)

Blanking and Cutting Errors

-

- Definition

- Curved (concave) clips (CW 6/29/15)

- Crescent curved clips

- Bowtie clips (ES Nov/Dec 2005; CW 6/16/14)

- Two large clips at opposite poles – ends rounded

- Four clips — punch slices through strip with normal hole spacing

- Struck chopped webbing

- Straight clips (CW 1/14/13)

- Smooth straight clips

- Irregular straight clips

- Sawtooth clips

- Incomplete straight clips (actually struck-in cutting burrs)

- Straight cutting burrs (CW 1/14/13, 5/16/16)

- Corner clips (“outside corner clip”) (CW 1/14/13)

- Assay clips (“inside corner clip”) (cross-classified with pre-strike damage) (CW 1/21/13, 6/12/17)

- Ragged clips (also listed under alloy errors)

- Incomplete punch (incomplete clip) (ES May/June 2005; CW 3/24/14)

- Elliptical (convex) clips (ES May/June 2005; CW 4/5/10, 7/11/11)

- Multiple clips and combination clips (CW 1/27/14)

- Blanking burrs (“rolling fold”) (ES Jan/Feb 2007; CW 1/31/11, 5/29/17, 9/4/23)

- COIN WORLD SPECIAL: article posted HERE

- Concave blanking burrs (CW 5/16/16)

- Punched-in scrap (ES May/June 2006)

Upset Mill Errors

-

- Coins struck on blank (“Type I planchet”)

- Abnormally weak upset (ES July/August 2005)

- Abnormally strong upset (best seen on off-center strikes)

- “Groovy edge” (possibly from worn groove in upset mill)

- Variation in cross-sectional shape of rim/edge junction of planchet

- Struck coin sent back through upset mill

- Abnormal upset (ES Sept/Oct 2005; CW 2/27/12, 11/21/16)

- Wide, flat edge

- Smoothly convex edge

- Abnormally wide proto-rim

- Squeezed-in debris (upset mill inclusion) (ES May/June 2006; CW 9/6/10)

- Foil-like metal wraps around edge onto one or both faces

- e.g. Copper foil on nickels (not from improper annealing)

- Metal wire wraps around edge onto one or both faces

- Pellet embedded in edge (CW 9/6/10, 9/22/14)

- Foil-like metal wraps around edge onto one or both faces

Edge design errors (impressed into planchet before strike) (includes security edge errors) (CW 6/27/16)

-

- Edge design missing

- Edge design present on normally plain edge (CW 6/27/16)

- Wrong edge design

- Edge design too high or too low

- Interrupted edge design

- Tilted edge design

- Broken edging die (CW 6/27/16)

Mispunched center holes (foreign only) (CW 1/7/19)

-

- Misaligned holes

- Double punched center holes

- One hole centered

- Both holes misaligned

- Overlapping holes

- Totally separate holes

- Irregular center holes

- Abnormally small hole

- Partial hole (from broken hole punch)

- Circular Indentation (partial penetration)

- Due to broken-off punch tip

- Unpunched center hole

- Hole punched in planchet meant for a solid coin

Annealing Errors

-

- Improper annealing (due to excessive heat, prolonged exposure to intense heat, or excessive oxygen in annealing oven) (replaces “sintered plating” and “copper wash”) (ES July/Aug 2010; CW 11/30/09, 2/8/10)

- Black, brown, red, coppery discoloration (includes “black beauty” nickels)

- Layer of copper, often peeling

- Improper annealing (due to excessive heat, prolonged exposure to intense heat, or excessive oxygen in annealing oven) (replaces “sintered plating” and “copper wash”) (ES July/Aug 2010; CW 11/30/09, 2/8/10)

Poorly annealed or unannealed planchets (hard, brittle planchets) (CW 3/14/11)

-

- Broken planchets and coins (CW 3/14/11, 9/18/23)

- Radial cracks in coin (usually struck out-of-collar)

Brittle coins (cross-classified with alloy errors) (CW 3/14/11)

Abnormally hard planchets (CW 12/17/12, 8/15/22)

-

- 1954-S nickels

- 1983-P nickels

- COIN WORLD SPECIAL: article posted HERE

- “Superclash” 2000-P nickel (CW 3/22/10)

On undersized or underweight planchets (CW 2/13/12)

Miscellaneous forms of mint discoloration

Plating Errors

-

- Incomplete plating

- Unplated cents (CW 10/26/15, 7/24/23)

- Cents struck on unplated or partly-plated foreign planchets (CW 3/10/14)

- Thin plating

- Thick plating (ES March/April 2009)

- Blistered plating

- Circular blisters

- Linear blisters

- Intact blisters

- Ruptured blisters

- Brassy plating

- Split Plating (CW 12/18/17)

- Cracked and Peeling Plating (CW 12/18/17)

Bonding/Bonding Mill Errors (ES, Sept/Oct 2002)

-

- Missing clad layer

- Full

- Before strike (CW 5/23/22)

- After strike

- Before rolling is completed (weight may be close to normal) (ES Sept/Oct 2002, Nov/Dec 2006; CW 5/28/12)

- Partial

- Before strike

- After strike

- Before rolling is completed

- Thin cladding

- With gaps

- Missing both clad layers (struck core)

- Core thickness (ES Sept/Oct 2003; CW 3/18/13, 2/3/20)

- Full thickness

- Full

- Struck Clad layer

- Separated after strike

- COIN WORLD SPECIAL: article posted HERE

- Separated before strike

- Struck by itself

- Struck on top of or beneath a normal planchet

- Separated after strike

- Clamshell separation (CW 1/28/13)

- Clad layer folded over before strike

- Missing core

- Partial

- Full (Coreless or all-clad coins) (CW 12/19/11)

- Missing clad layer

Irregular planchets

-

- Scraps/fragments (CW 12/21/09, 1/27/20)

- Normal alloy/composition

- Off-metal

- Feeder finger material

- Foil

- Heavier than normal coin of same denomination

- Wider than normal coin of same denomination (along at least one axis)

- Ragged clip (cross-classified with alloy errors)

- Ragged notch (cross-classified with alloy errors)

- “Blowholes” (cross-classified with alloy errors)

- Fissures (cross-classified with alloy errors)

- Cracked planchets (cross-classified with alloy errors)

- Scraps/fragments (CW 12/21/09, 1/27/20)

Pristine Planchets (i.e. lacking tumbling marks) (CW 1/11/16)

Pre-Strike Damage (CW 11/15/10, 11/15/10, 1/23/12, 1/30/12, 12/15/14, 4/13/15, 6/8/20)

-

- COIN WORLD SPECIALS: articles posted HERE and HERE

- Assay clips (cross-classified with blanking errors)

- Rim burrs (CW 1/31/11)

- Accidentally and intentionally “re-sized” planchets (CW 9/15/10)

- “Crimp marks” (mostly found on off-metal errors, e.g., 5c/1c, 5c/10c)

- Rockwell test mark in planchet (circular or oval dimple) (ES July/Aug 2006; CW 10/15/18)

- Planchet with adjustment marks (gold and silver planchets filed to return heavy planchets to normal weight)

- Edge rolled, squeezed, and folded-over (or with thin apron produced) (CW 11/15/10, 1/23/12, 6/15/20)

- Pre-plating damage (zinc cents) (CW 1/23/12)

- Post-plating damage (zinc cents) (CW 11/15/10)

- Scraped-in debris (CW 2/23/15)

- Repetitive pre-strike damage (CW 12/15/14)

- Other forms of pre-strike damage

- Gouged (CW 1/14/19)

- Crushed (CW 4/13/15)

- Scraped (CW 2/23/15)

- Torn

- Crumpled (CW 8/15/11)

- Gouged (CW 1/14/19)

Inter-strike Damage (CW 1/9/12, 8/20/12)

-

- Cancelled or defaced between strikes (CW 3/25/13)

Trans-strike damage (CW 7/12/21)

Wrong planchet and off-metal errors

-

- Wrong planchet, correct composition

- Off-metal

- Domestic planchet (CW 6/22/20)

- Monroe dollar coin struck on a clad dime planchet

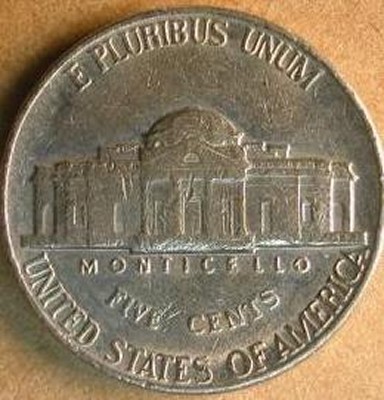

- 1987-P Jefferson nickel struck on clad stock

- Domestic struck on foreign planchet

- 1941-P Lincoln cent struck on a Panama 1¼ bronze centesimos

- 1920-P Lincoln cent struck on a Argentina 10 centavos planchet

- 1905-P Barber dime struck on a Panama or Philippines five centavos planchet

- 2000-P Sacagawea struck on a Ghana 100 Cedis ring

- Foreign planchet

- Unidentified origin and purpose (orphan) (ES Sept/Oct 2006, Nov/Dec 2006, March/April 2011, May/June 2011; CW 5/10/10, 12/19/11, 1/30/17, 11/30/20, 4/4/22)

- Defective and damaged off-metal planchets (CW 3/21/16)

- Foreign denomination struck on U.S. planchet

- 1970 Philippines 25 Sentimos on a U. S. cent planchet (3.1 g)

- 1972 Philippines 1 Peso on a U.S. clad 50 cent planchet

- 2000 Canadian Pride 25 cent coin struck on a United States nickel planchet

- Pure copper quarters and dimes (covered under bonding mill errors)

- Pure clad dime (covered under bonding mill errors)

- Domestic planchet (CW 6/22/20)

- Wrong stock errors

- Correct composition

- Off-metal (e.g, 1987-P nickel struck on clad quarter stock) (CW 4/22/13, 9/23/13, 9/10/18)

- Transitional stock planchets (CW 9/23/13)

- Business strike on special off-metal planchet (CW 2/10/20)

- (e.g., 40% silver-clad 1974-D and 1977-D Eisenhower dollars)

- Special strike on business planchet (CW 2/10/20)

- (e.g., 1973-S Eisenhower dollar on Cu-Ni clad planchet)

- Business strikes on proof planchets (CW 11/14/11)

- Proof strike on business planchet

- COIN WORLD SPECIAL: article posted HERE

- Wrong date error (covered under mules and die manufacturing errors)

- Double denomination errors (CW 10/3/22)

- Same year

- Different year

- Over pre-existing wrong planchet/off-metal error (ES Sept/Oct 2017; CW 2/10/2014)

- Dual country (CW 3/21/11)

- Same year

- Different year

- Intentional overstrikes (not an error)

- Transitional planchet errors (“wrong series”) (ES Sept/Oct 2001; CW 3/28/16, 8/22/16)

- Composition/year mismatch with non-overlapping production schedule

- 1943 bronze cents (CW 4/11/16)

- Composition/year mismatch with overlapping production schedule

- 1965 silver dimes and quarters

- 1964 clad dimes and quarters

- Intra-year design/composition mismatch

- 1991 Russia 10 kopek (ES Sept/Oct 2001)

- Forward-jumping transitional planchet errors (CW 3/20/17)

- Transitional/wrong denomination error

- (e.g. 1965 quarter struck on silver dime planchet)

- “Long pause” transitional planchet errors (CW 4/5/21)

- Composition/year mismatch with non-overlapping production schedule

- Struck on smaller planchet or coin

- Struck on same size planchet or coin

- Struck on re-sized planchet (dime design struck on cut-down cent planchet)

- Struck on larger planchet or coin (CW 8/22/22)

- 1981 cent on nickel planchet, uniface reverse

- 1981 dime on cent cap

- 1981 cent design struck on Susan B. Anthony dollar (several known)

- 2006 Chilean 10 pesos struck on a 100 pesos bi-metallic planchet

- Canadian “assisted errors” 1977 – 1981

- Malaysian “assisted errors” 2005-2007

- Struck on loose clad layer (covered under bonding mill errors)

- Weld seam planchets (controversial) (CW 9/24/12)

- Coins struck on washers, gears, and other hardware

- Coins struck on “aluminum” feeder fingers

- Experimental issues (CW 11/23/15, 5/23/16)

- Experimental wartime planchets (CW 12/7/09, 12/21/09)

- 1999 and 2000 state quarters on experimental planchets – tests for Sacagawea dollar (CW 11/26/01)

- 1999 Susan B. Anthony dollars struck on experimental planchets (CW 8/5/02)

- 1974 aluminum and bronze-clad steel cents (CW 1/13/03)

Bi-metallic errors (foreign only) (ES Nov/Dec 2005)

-

- Misaligned core (ES May/June 2007; CW 3/6/23)

- Misaligned center hole (ES Sept/Oct 2007)

- Well-seated core (CW 3/6/23)

- With misaligned core (CW 3/6/23)

- Double-punched center hole

- Unpunched center hole

- Solid disc of ring metal (CW 3/26/18)

- Solid disc of ring metal with embedded core

- Solid disc of ring metal with core indent

- Ring with incomplete punch (ES Sep/Oct 2007)

- Core with incomplete punch

- Struck outer ring (ES Jan/Feb 2007)

- Struck core (ES Nov/Dec 2006)

- From another denomination

- From another country (ES Sep/Oct 2009, Nov/Dec 2011)

- Struck by solid-denomination dies

- Wrong core inserted (ES Sep/Oct 2013; CW 10/17/22)

- Core-sized scrap disc of ring material inserted into disc

- Wrong ring (ES March/April 2007; CW 10/10/22)

- Ring accidentally punched from solid planchet

- Ring accidentally punched from solid coin (ES Nov/Dec 2008)

- Struck ring from another country (restruck)

- Struck core from another country (restruck)

- Unstruck core inserted into struck ring and then restruck

- Abnormally small core (controversial)

- Abnormally wide center hole (controversial)

- Abnormally thin core

- Abnormally thick core

- Abnormally thin ring

- Abnormally thick ring

- Incomplete trilaminar core

- Missing one layer (ES Mar/Apr 2010)

- Missing two layers

- Core punched out of ring strip

- Ring punched out of core strip

- Bi-metallic planchet struck by solid-denomination dies

- Solid-denomination planchet struck by bi-metallic dies (ES Mar/Apr 2014)

- Bi-metallic planchet struck by wrong bi-metallic design