Part V. Planchet Errors:

Rolling Mill Errors:

Rolled-thin planchet

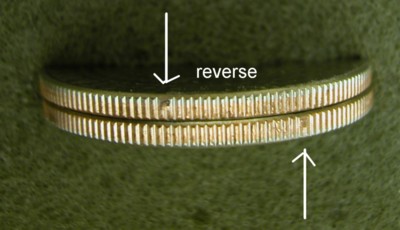

Rolled-thin planchet: A coin struck on a planchet punched out of stock that was rolled too thin on the rolling mill.

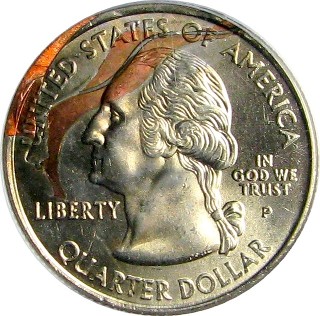

This 1974 quarter was struck on a rolled-thin planchet. It weighs 4.92 grams instead of the normal 5.67 grams.

|

|