Part IV. Die Errors:

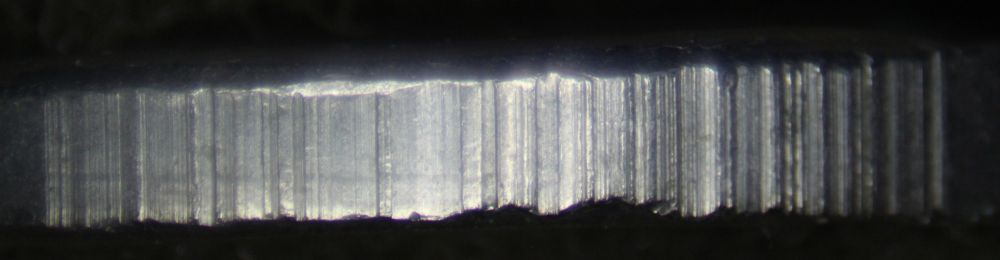

Collar Manufacturing Errors:

Wide Collar

Definition: A coin struck inside a collar whose diameter is wider than normal. This rare error is subtle and is often only detected when an otherwise normal-looking coin gets stuck in a plastic storage tube or won’t fit in its designated hole inside a cardboard Dansco album.

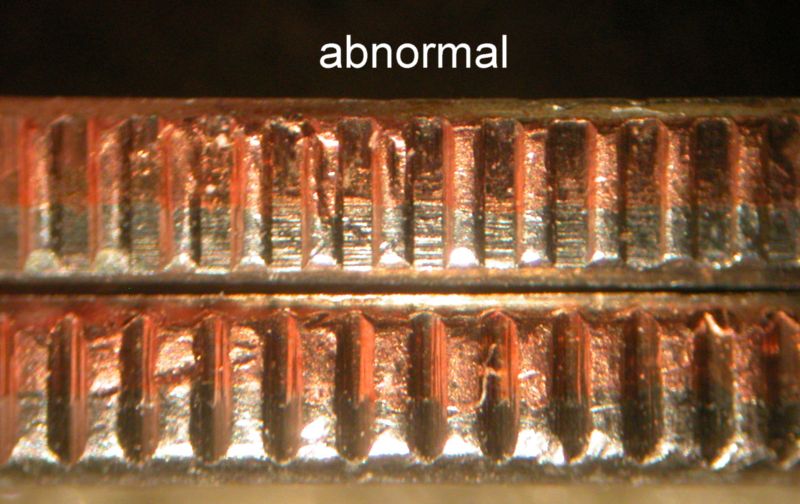

An abnormally wide collar can arise in several ways:

hammered into the collar opening.

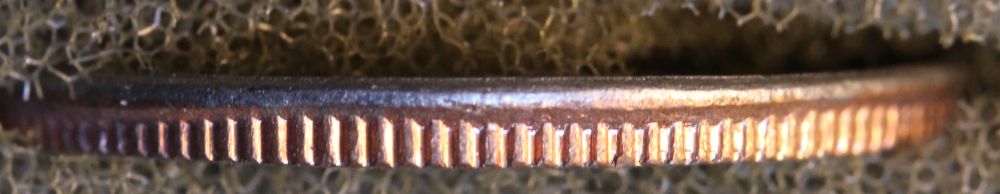

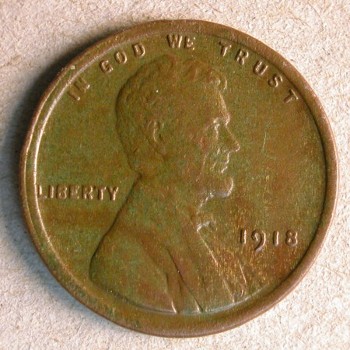

This 1918 cent was struck in a collar that expanded due to the presence of four vertical collar cracks. Its diameter

measures 19.45 mm instead of the normal 19.05 mm.

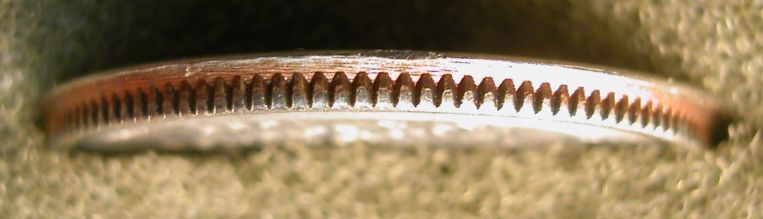

The above 1999-P dime was struck in an abnormally wide collar. The diameter of this dime measures 18.24 mm instead of the normal 17.91 mm. It’s likely that the collar expanded due to the relentless pounding involved in restraining hundreds of thousands of planchets. The edge is slightly convex in vertical cross-section, which is consistent with this scenario. This dime also shows a case of surface film transfer on the obverse face. This type of error occurs when the preceding coin is double struck with movement between strikes. If either the coin or the die is grimy, a shadow image of the first strike is transferred to the die face and then transferred back to the next planchet.

For more information on wide collar errors see the May 17, 2010 Coin World.