Part V. Planchet Errors:

Upset Mill Errors:

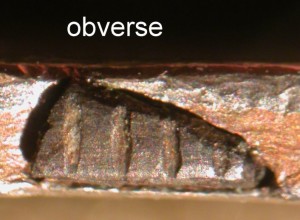

Squeezed-In Debris

Definition: There are numerous entry points inherent in the minting process that allow foreign material to embed itself into a blank, planchet or coin. A relatively uncommon entry point occurs in the upset mill. The grooves in the upset mill can trap material that is then transferred to the edge of a blank as it is transformed into a planchet. There are two major forms of “squeezed-in” debris, discrete pellets and broad, thin sheets of metal. In the case of the former, small bits of metal or other foreign matter are forced into the edge of the planchet. In the case of the latter, thin sheets of metal — often with a composition strikingly different from the coin itself — wrap around the edge of the planchet, and are eventually struck into one or both faces as well as the coin’s edge.

Embedded in the edge of this 1968-D cent is a small pellet of non-magnetic, nickel-colored metal.

Embedded in the edge of this 1968-D cent is a small pellet of non-magnetic, nickel-colored metal.

Embedded in the edge of this 1998-P half dollar is a small piece of ferromagnetic metal (probably steel).

Embedded in the edge of this 1998-P half dollar is a small piece of ferromagnetic metal (probably steel).