Part X. Wastebasket and Composite Categories

Embedded Debris

Scraped-In Debris

Definition: There are many entry points in the minting process during which foreign matter can end up embedded in a planchet or coin. The rarest type of embedded debris (1 known case) is scraped-in debris. Here foreign matter is left embedded in a blank or planchet when the disc is scraped against a debris field. The embedded object or objects persist through all subsequent steps in the minting process

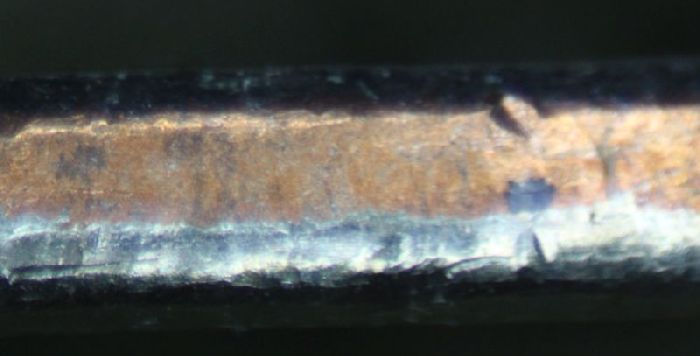

This 2002-P Indian quarter dollar was struck on a heavily damaged blank or planchet. Despite the excruciatingly severe damage, the coin still ended up in a Mint Set. Both faces of the planchet show deep scratches. On the reverse face, a particularly wide, deep gouge terminates in a piece of black debris. The width of this particle precisely matches the trailing groove, proving that the particle’s movement across the face of the planchet was responsible for the groove.

The planchet also shows matching, shallow, C-shaped depressions on the left side of both faces a short distance in from the rim. They represent crushing damage. These ill-defined depressions thinned the planchet in this area, which is why the peripheral letters did not strike up completely.