Part VII. Post-Strike Mint Modifications:

Embedded Matter:

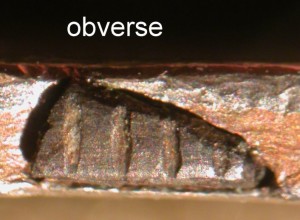

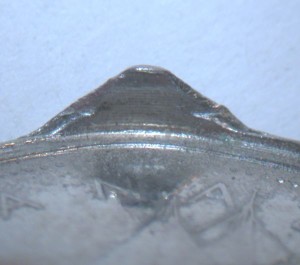

Lettering Die Inclusion

Definition: Foreign matter that is forced into the edge of a manganese-brass clad dollar coin by the lettering die. Such errors may be difficult to distinguish from foreign matter forced into the edge of a planchet during the upsetting process. The main difference is that a lettering die inclusion will protrude from the coin’s edge while an upset mill inclusion will be flush with the edge.

This 2007-P Jefferson dollar has a spiral metal shaving embedded in its edge. Strongly attracted to a magnet, it’s probably composed of steel. The right arm of the U of PLURIBUS is deeply impressed into the metal shaving because of the latter’s tight fit against the lettering die. Discovered by Troy Shoopman.