Part IV. Die Errors:

Collar Clash:

Floating Collar Clash:

Definition: A piece of a collar breaks off, lands between the dies and is struck. One or both dies are left with an impression of the collar. Depending on how it’s struck, a piece derived from a reeded collar may leave a series of grooves or a gear-like impression in the die face.

As a practical matter, only reeded collars are likely to leave an impression that can be distinguished from die damage arising from other causes. And even the impression of a reeded collar can be confused with the impressions of other threaded, toothed, ridged, or serrated objects. Therefore, the presence of an accompanying die break is quite helpful in establishing the diagnosis.

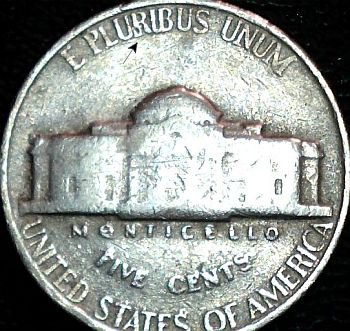

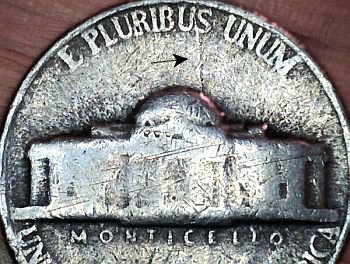

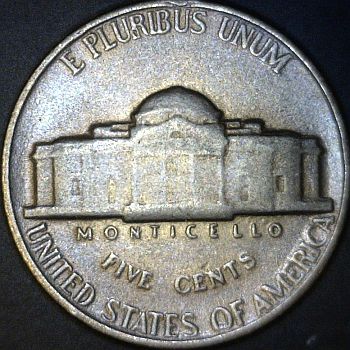

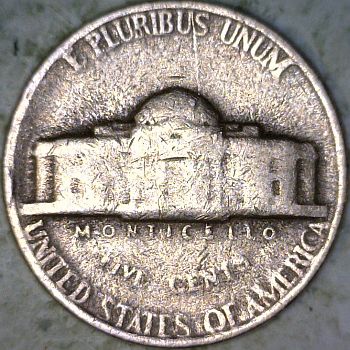

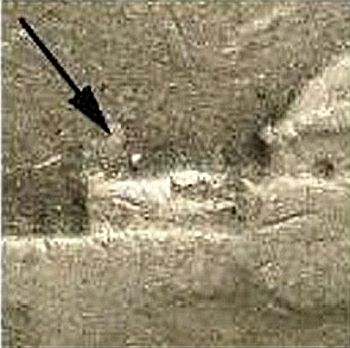

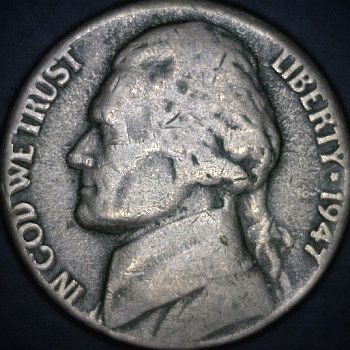

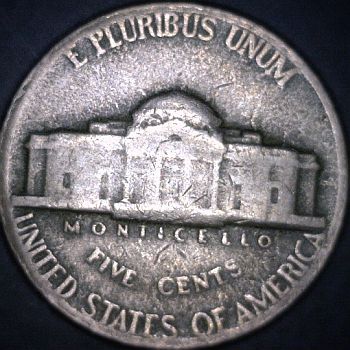

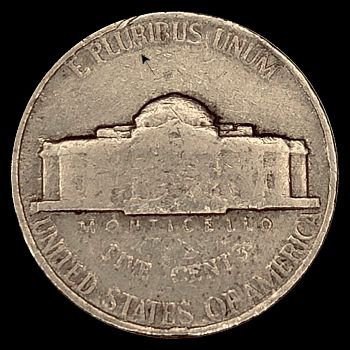

This 2007 Denmark 2 kroner coin features a collar break at 11:00 (reverse clock position) and a floating die clash at 10:00. This denomination has an edge with intermittent reeding. The collar fragment left an impression of four ridges in the reverse die face as well as an impression of the collar’s beveled entrance.

A close up of the floating collar clash.

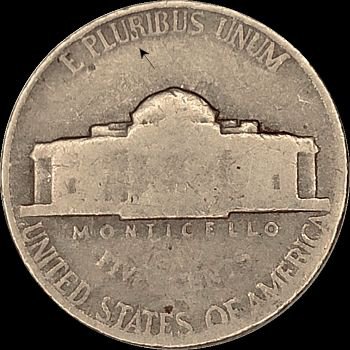

A close up of the collar break.