Part XI. Non Errors:

Altered Coins:

Dryer Coins

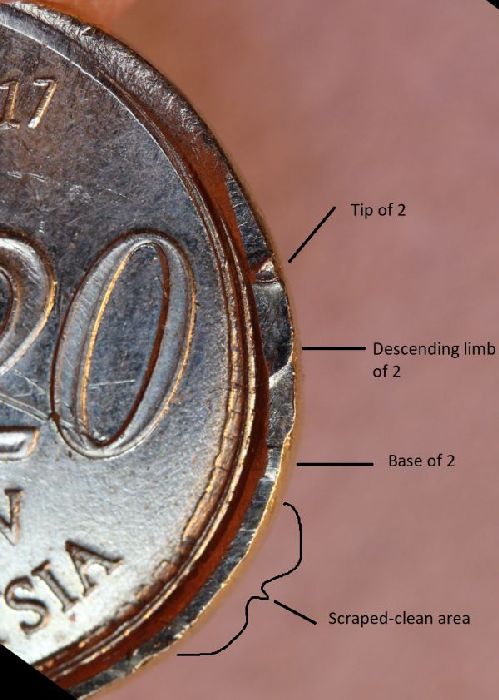

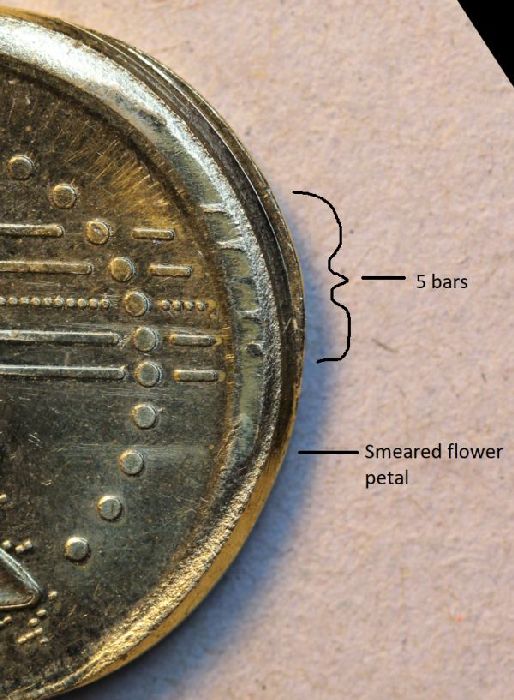

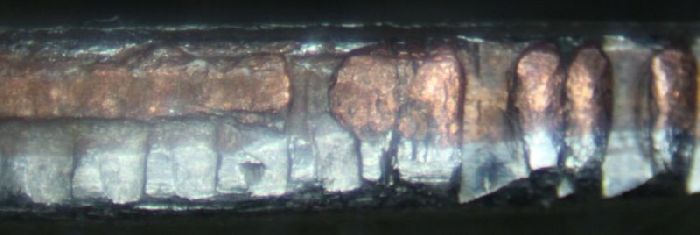

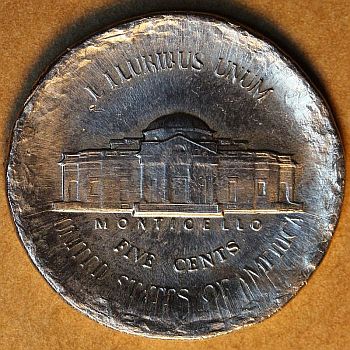

Definition -This term is used in reference to abused coins that have tumbled around inside of an industrial dryer. The coins tend to get trapped in between the inner and outer tubs of these dyers and then are subject to repeated cycles of being battered against the hard surface in the heated chamber. The obverse and reverse designs have been pummeled into mush. Some metal has been relocated from the edge and design rim onto the field and peripheral letters in the form of a thin apron. The apron forms a complete ring that lies loosely on each face. For more information and examples of dryer coins, please see this thread: https://www.coincommunity.com/forum/topic.asp?TOPIC_ID=143863

The images above are of a 1964 Jefferson Nickel.

Images courtesy of Harley Handzel.