Part V: Planchet Errors:

Alloy Errors:

Intrinsic metallic inclusions

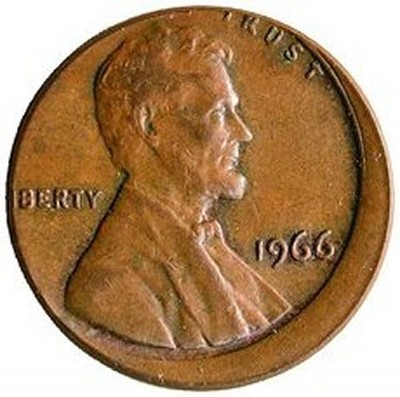

Definition: An intrinsic metallic inclusion includes all situations in which metal of a non-standard composition somehow resists melting or otherwise manages to maintain its integrity within the molten alloy.

This 1948 cent displays a large strip of light gray metal running across the obverse face. Close inspection reveals that the metal inclusion is an intrinsic part of the coin metal strip, present from the very beginning. It probably represents a globule of unmixed zinc or tin.

Images are courtesy of Heritage Auctions.