Part IV. Die Errors:

Die Cracks:

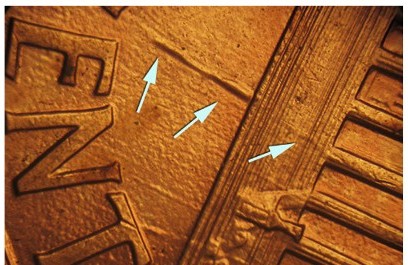

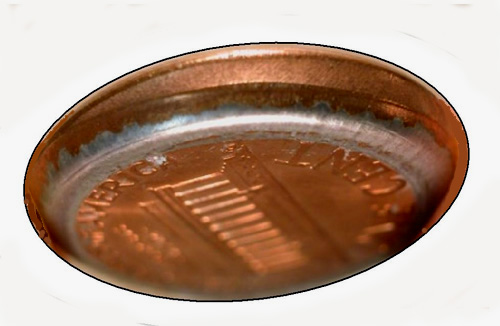

Bilateral, Radial, Antipodal Die Cracks

Definition: Radial die cracks that develop at opposite poles and converge toward the center of the die face. These are often mistaken for split dies. The difference is that these cracks do not meet in the center. Distinguishing between radial antipodal die cracks and split dies is made difficult by the frequent occurrence of a central zone of subsidence in both types of errors. In other words, the die face tends to sink in and the design becomes unclear or non-existent within the zone of subsidence.

The reverse face of this 1974-D nickel shown above has a pair of radial, antipodal die cracks. These cracks fail to meet in the center of the design and are not aligned with each other. Although there is a die subsidence error in the center of the die face, the central design remains clear enough to establish that no crack crosses it from one end to the other. The crack extending in from the left side peters out as it enters the top of Monticello’s staircase. The crack that extends in from the right pinches out as it meets the column on the right.