PART IV. Die Errors:

Cuds:

Crescentic Cud

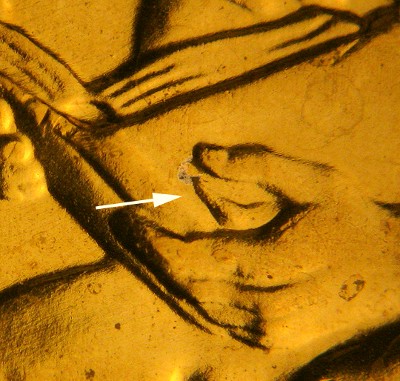

Definition: A relatively uncommon form of cud is the crescentic cud. As the name implies, a crescentic cud is long and thin, and follows the curvature of the die. It results when the outer margin of the die neck breaks away.

Crescentic cuds reflect the presence of a circular or semi-circular zone of weakness somewhere near the periphery of the die neck. Contributing causes may include improper heating, cooling, tempering, or quenching of the die. This creates a boundary zone across which the hardness and brittleness of the die steel changes abruptly. Under stress, the outer part of the die neck would tend to crack and break off.

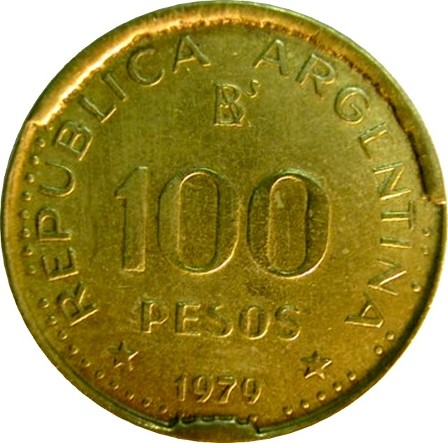

Depicted below is an Argentina 100 pesos with a long, thin, crescentic cud on the obverse face. A small ovoid cud is located at the opposite pole.