PART IV. Die Errors:

Die cracks:

Arcing rim-to-rim die crack (a.k.a., pre-cud)

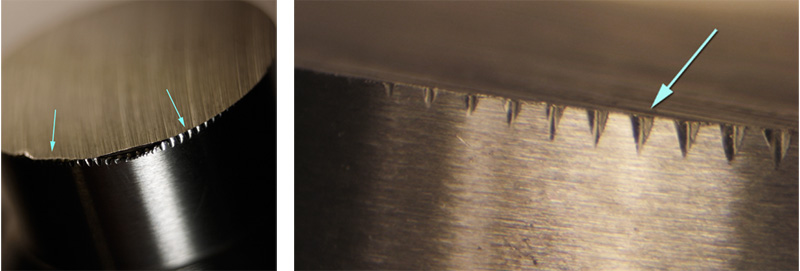

Definition: A die crack that follows a curved trajectory from one point on the rim to another. The area of the die face cordoned off by such a crack generally amounts to less than 40% of the total area. The die crack shows only lateral spread. The presence of either vertical displacement or horizontal offset would indicate the presence of a retained cud. If the lateral spread exceeds half-a-millimeter, it should be labeled a curved, asymmetrical split die.

An arcing rim-to-rim die crack may progress to a retained cud, a cud, or an asymmetrical split die.

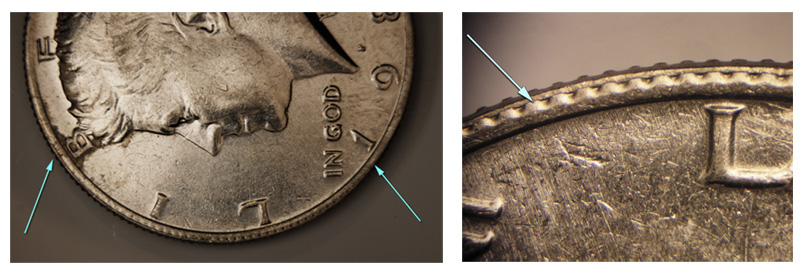

A prominent pre-cud die crack is present on the reverse of the 1985 cent depicted below. There is no vertical displacement or horizontal offset, so one must assume this area was still attached to the main portion of the die. It also has a large cud in the SE quadrant of the reverse. In addition to that it shows a curved, roughened area of die damage in the NW quadrant caused by a collision between the reverse die and the broken surface of the loose die fragment. That collision might have caused the die to crack in this area.

Below is the reverse of a 1985 cent that shows (1) a large cud in the SE quadrant, (2) a “pre-cud” die crack in the NW quadrant, and (3) a curved, roughened area of die damage in the NW quadrant. The die damage is from a collision between the obverse die and the die fragment that broke away from the SE quadrant.

Close-up of the pre-cud die crack. It could conceivably have worsened to become a cud, a retained cud, or an asymmetrical split die.