PART V. Planchet Errors:

Dual Denomination: Same Year

Definition: A coin is struck a second time by dies belonging to a different denomination

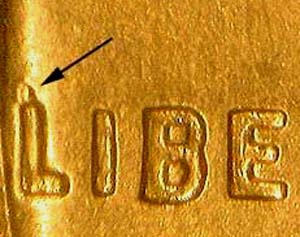

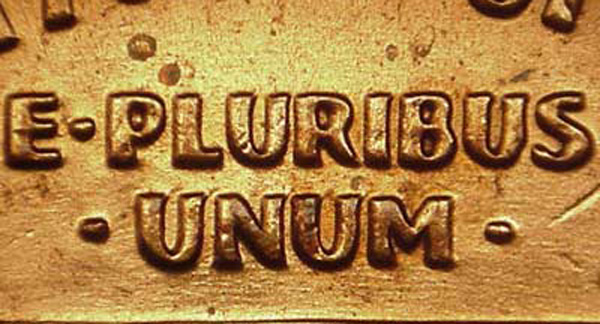

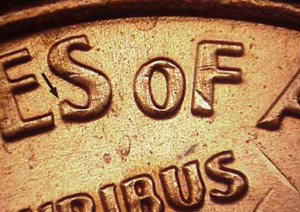

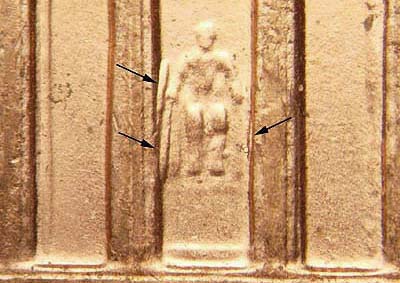

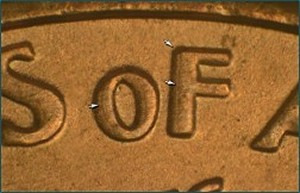

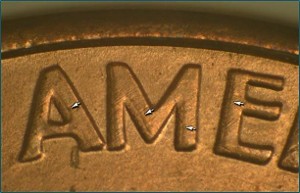

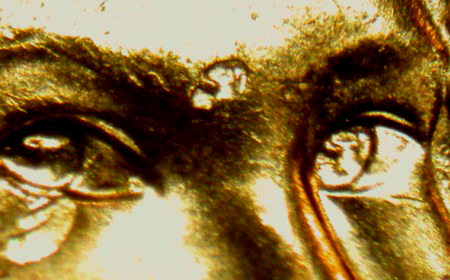

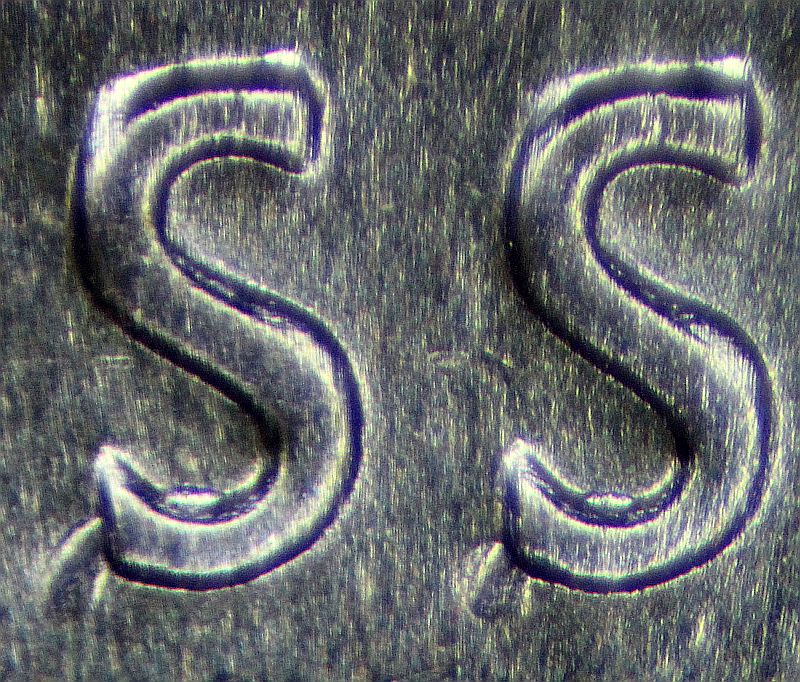

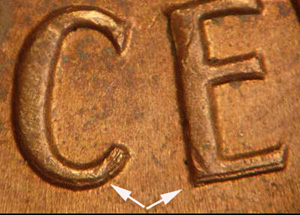

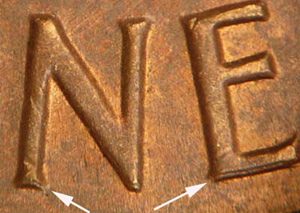

This 2000 cent was struck a second time by dies carrying the design of a 2000-D nickel.

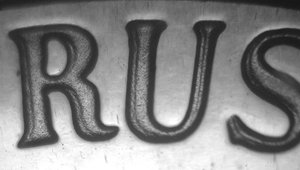

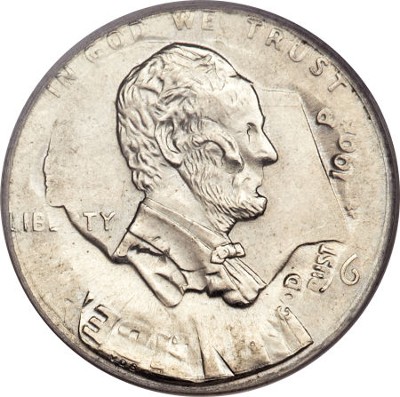

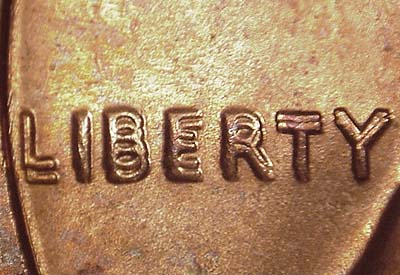

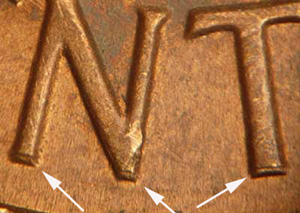

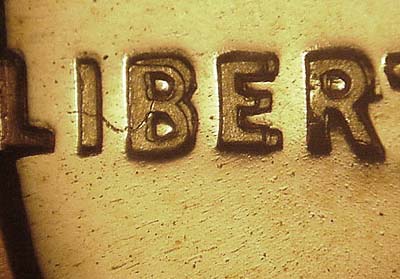

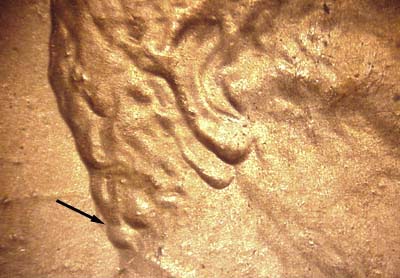

This dime planchet was first struck by 1995P Roosevelt dime dies. It was then re-restruck by 1995P Lincoln cent dies.

Photographs are courtesy of Coppercoins.

Photographs are courtesy of Coppercoins.