PART VI. Striking Errors:

Brockages:

Clashed Cap Strike:

Counterbrockage/Clashed Cap Strike

Definition: This is one of the eight ways in which a brockage-counterbrockage error can be generated. In this scenario, an obverse die cap that is striking counterbrockages clashes with the reverse die when a planchet fails to be fed into the striking chamber. The working face of the die cap picks up an incomplete set of reverse design elements while, at the same time, some of the incuse, mirror-image elements on the working face of the cap are erased. The next planchet to be fed into the striking chamber after this event is left with a sharp, incomplete, unexpanded brockage and a scattering of counterbrockage elements.

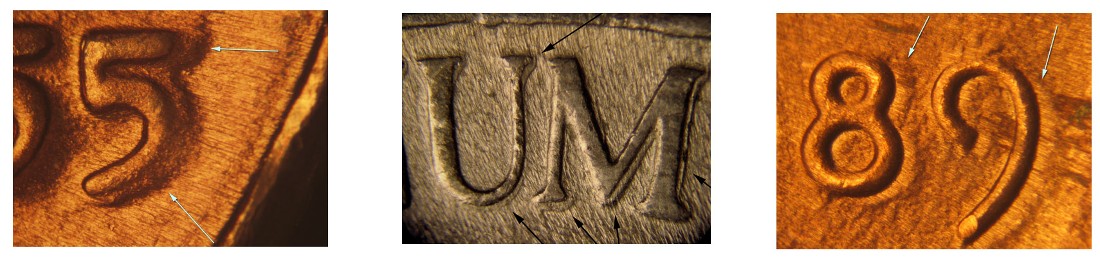

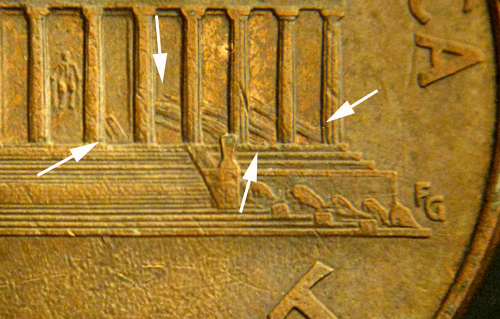

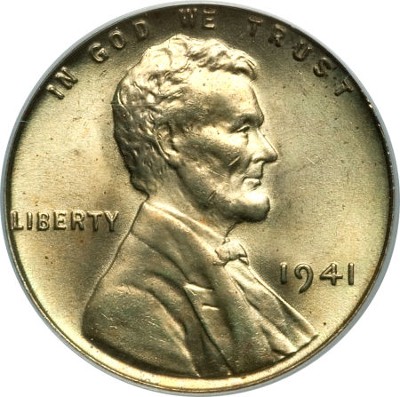

The 19XX Lincoln cent above shows an expanded counterbrockage and an incomplete secondary brockage (first impression). The brockage is derived from elements transferred to the working (reverse) face of the die cap during the clash. The semicircular elevation on the right represents an indent on the working face of the die cap. The die cap struck a planchet that was fed partway into the striking chamber. This presumably occurred prior to the clash.