PART IV. Die Errors:

Die Damage:

Intentional Die Abrasion:

Heavy Die Scratches

Definition: Die scratches are fine lines left in the die face by intentional or accidental die abrasion. Die scratches produced by intentional die abrasion usually travel in many different directions.

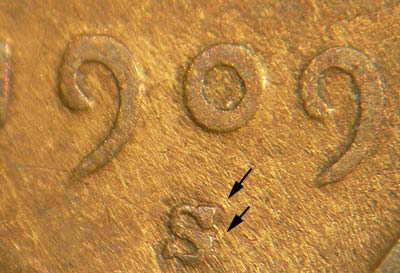

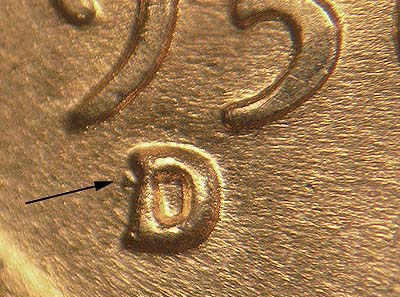

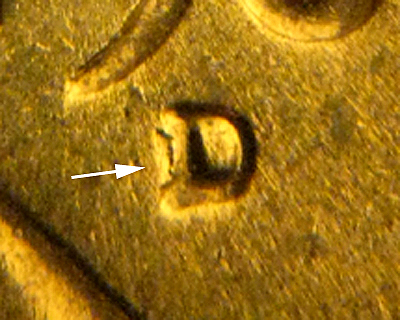

The images below show a 1983P Jefferson nickel with heavy die scratches. These scratches were left by the intentional abrasion of both the obverse and reverse dies to remove a strong die clash. Notice the varying length and random directionality of the numerous lines, which is typically seen when a die clash is removed.