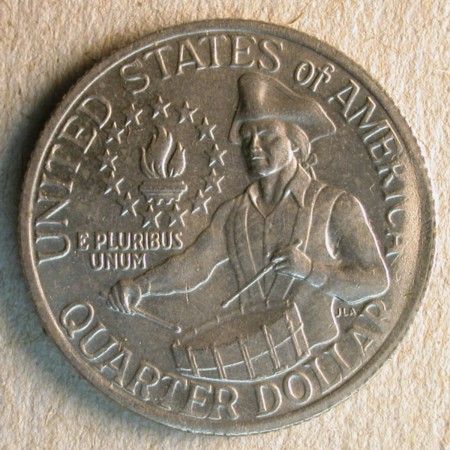

PART III. Die Installation Errors:

Mismatched Business / Proof Dies

Subtle differences in design details often differentiate dies intended for business strikes and those intended for proof strikes. Cases of mismatched proof and business strike dies (sometimes called Wrong Design errors/varieties) have been plentiful. Cases sometimes appear to be dies seemingly meant for proof coinage, being used mistakenly without proof finishing, used on business class strikes (or vice versa). It has been suggested in some circumstances that proof dies (on ’56-’64 quarters & ’56-’63 halves) after an initial run, could have been used on business strikes to reuse them instead of discarding them (though specific evidence is needed to prove this hypothesis). Whatever the case, they can make for an interesting rarity to keep an eye out for.

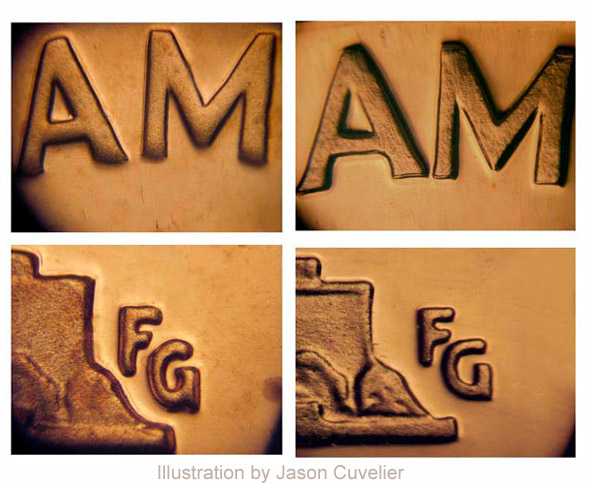

Below are the two known reverses for 1998-S & 1999-S proof Lincoln cents, the CAM (on right) is the desirable (rare) version made from a business strike die.