Part III. Die Installation Errors:

Inverted Die Installation (Not An Error):

Re-introduction (earliest example)

Definition: The inverted die setup employs the obverse die as the anvil die. This setup has been used sporadically over the last 200+ years and was slowly re-introduced in the last decade of the 20th century. The inverted setup is mainly associated with the high-speed Schuler press, although exceptions exist. Until recently, the earliest modern examples of coins struck with the inverted setup were a few 1992-D quarter dollars. Recently, a 1989-D quarter dollar struck with the inverted setup was recognized. It may represent an informal or even unauthorized test of the setup, as discussions on “changing the orientation of the reverse die in presses” don’t appear in the annual Mint report until fiscal year 1990.

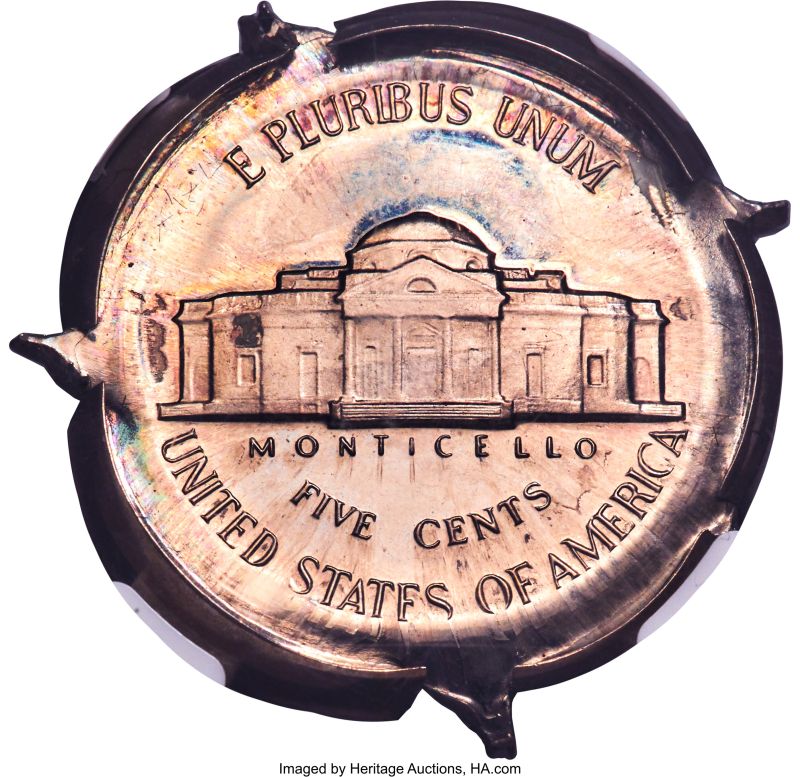

Several clues tell us that this 1989-D quarter was struck with inverted dies:

(1) The reverse design rim is far better defined and far more complete than the obverse design rim.

(2) Signs of collar contact appear along the edge of the unstruck obverse crescent.

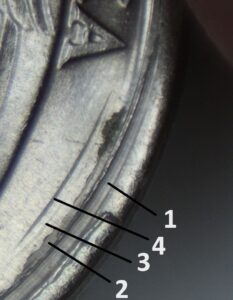

(3) The reverse shows four single-downstroke strike lines (numbered on close-up image). Multiple strike lines produced by a single downstroke are known only on the face struck by the hammer die.