Part V: Planchet Errors:

Alloy Errors:

Split planchets, Before strike

Definition: Split planchet errors are normally restricted to planchets composed of a solid alloy. Among U.S. coins, cents and nickels are the most commonly affected denominations. Split planchet errors should not be confused with “separation errors”, which only affect clad and plated coins. Separation errors are bonding errors, not alloy errors.

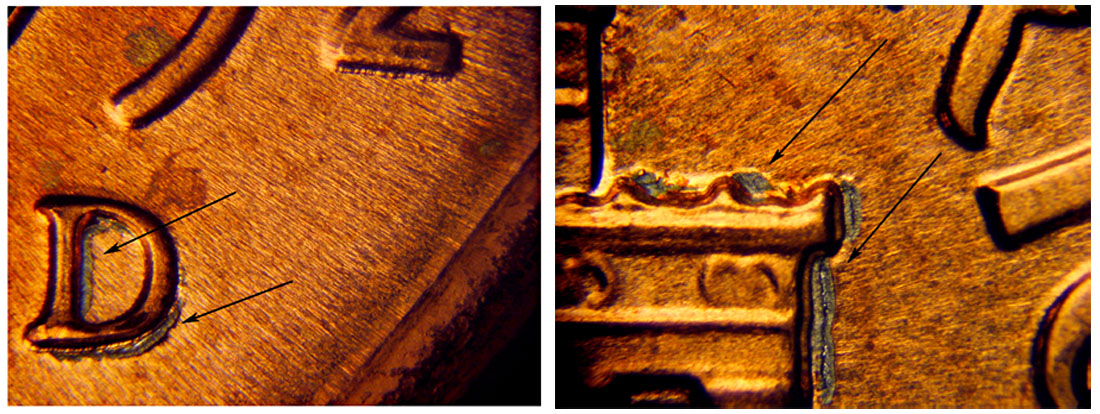

A coin struck on a split planchet will always weigh less than a normal coin. A coin struck on a split-before-strike planchet will show a pattern of striations on the split face. The texture of the striations varies from coarse to fine. If a strike is unusually strong, most of the striations may be effaced. However, most split-before-strike planchets show a weak strike, because the thinner planchet is closer to the minimum die clearance.

Shown below is a 1961-D cent struck on a split planchet. The pattern of striations is unusually coarse.

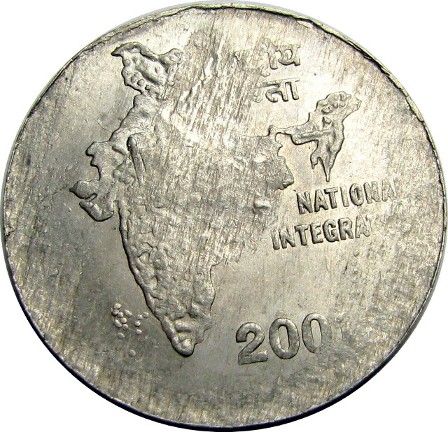

The two rupee Indian coin below is comprised of a nickel alloy. This planchet weighs 3.2 g, well below the normal 6.0 g. The obverse face has an expected weak strike with much design detail absent. The reverse face shows coarse striations with a combination of weak and strongly struck design.

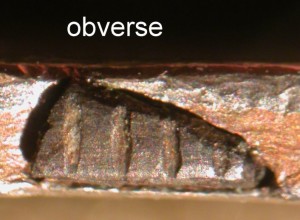

Approximately half the reverse face of this 1888 shield nickel peeled off before the strike. This part of the coin was

consequently left too thin for any design to strike up.

Images are courtesy of Heritage Auctions.