Part III. Die Installation Errors:

Transitional Reverse (Minor temporal mismatches):

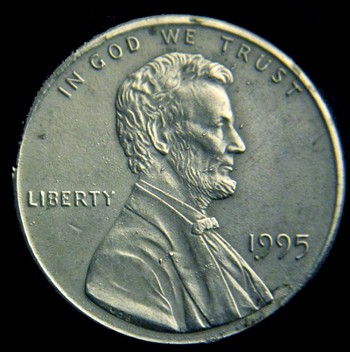

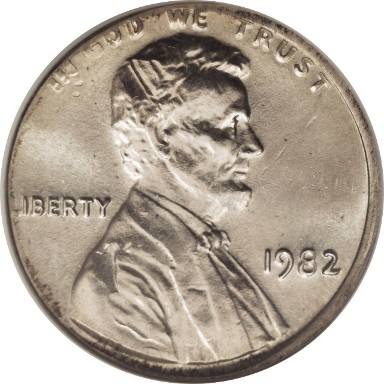

1992 (P) and 1992-D cent with (Close AM) reverse

Definition: Subtle differences in design details can differentiate dies used in different years. Whether accidental or purposeful, obverse dies are sometimes mated with a reverse die meant for a previous or subsequent year. These are often called “transitional reverses”. Well-known examples include 1992(P) and 1992-D Lincoln cent obverses mated to a 1993 reverse.

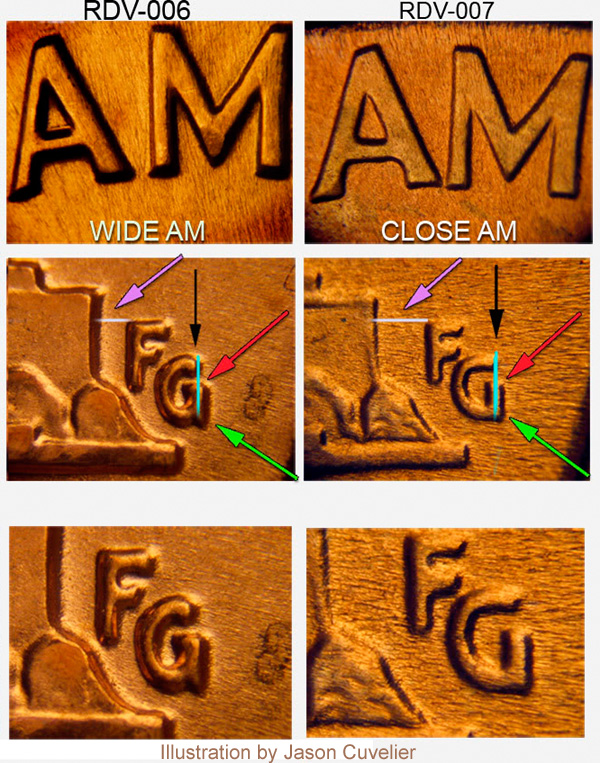

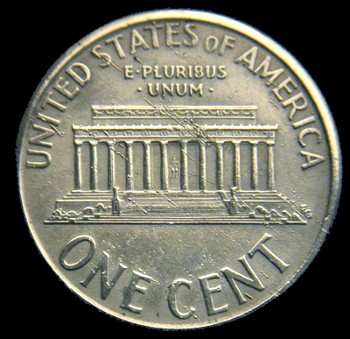

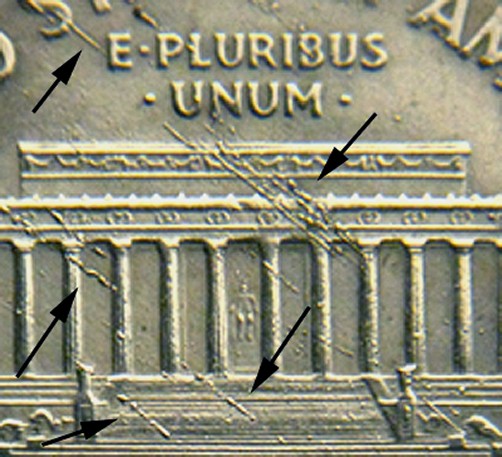

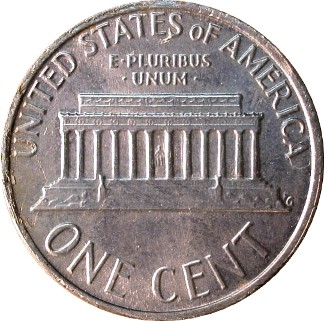

Shown below is the normal reverse for 1992 (left) and the reverse of 1993, otherwise known as the Close AM or CAM reverse. A few 1992 obverse dies from both the Philadelphia and Denver Mints were paired with the reverse of 1993. The most noticeable difference between the two reverses pertains to the distance between the A and M of AMERICA. There is hardly any gap between the two letters in the Close AM style. The font used for the designer’s initials (“FG”) is significantly different between the two reverses as well.

The normal, Wide AM reverse is found in Lincoln cents from 1989 until 1992. After that, the Close AM style became normal for business strikes while the Wide AM style became normal for proofs.