|

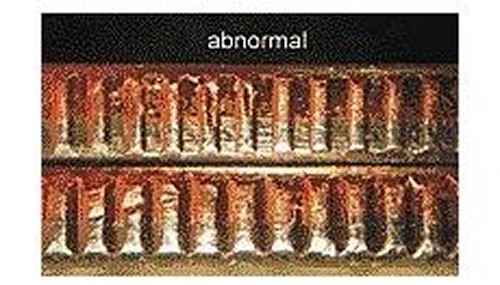

Machine parts above By Mike Diamond | 05-21-11 As a coin is struck, its expansion When the collar fails to deploy, a On some occasions a coin’s expansion The most familiar obstacle to A typical example is shown here in Sideneck strikes are always concave Strike-related edge damage of In either case, we can’t be sure The introduction of the Schuler The dies evidently struck whatever This type of edge damage can be The affected coins all show a sequence Coin World’s

2011 05 30

|

Machine By Mike Diamond | May 21, 2011 | ||||||

|