Part II. Die Varieties:

Doubled Dies:

Class IV (Offset Hub Doubling)

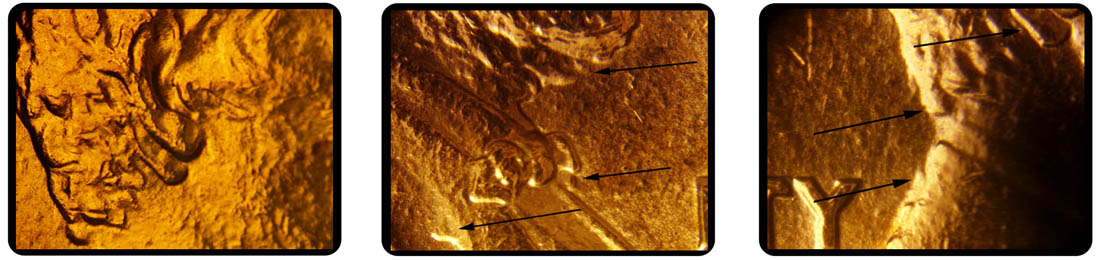

This class of Doubled Die is produced when two hubbings have their centers misaligned. It is characterized as having doubling that is evenly spread in one direction. The doubling is unlike that found on Classes I or V, where the misalignment-event shows a rotation at or near the center (I) or at or near the rim (V). Doubling is often rounded, found closer to the center, and when identified on numeric or alphabetic characters, shows notching.

It has been hypothesized that the reason many examples do not show doubling near the rim is because one of the hubbings only received an uncharacteristically incomplete hubbing. Such an incomplete hubbing would result in design elements not being pressed deep enough in the middle of the die, and not at all along the perimeters. The die originates in a conical shape until it is completely pressed down, if the incomplete hubbing was the first, the outer devices may not have been hubbed the first time around.

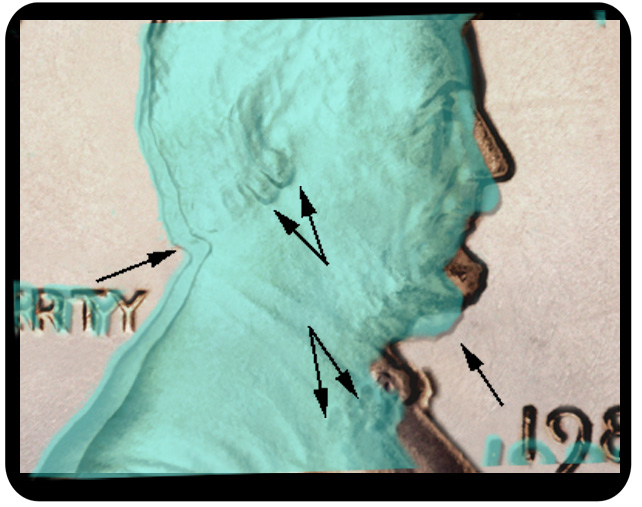

Below is a facsimile of a fictitious 1960P with a strongly doubled Class IV DDO. In this case the first hubbing would have been centered and complete, with the second hubbing having its center oriented N-NE from the first. It should be noted that this example is showing universal doubling on all design elements (including the whole portrait) which has never been documented but shown for effect.

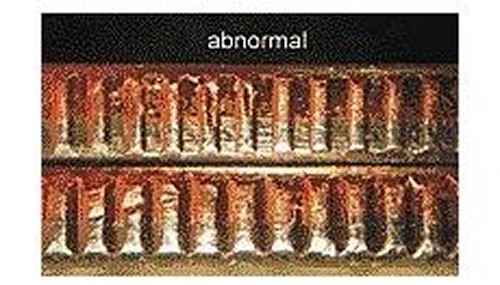

Below is 1983 DDR-001, which exhibits a large spread going North, it is stronger than the above hypothetical illustration. The ’83 DDR shows strong peripheral doubling. The central elements show some doubling around the parameter of the memorial and in a few sections of the building itself (like the upper portions of the columns). Notice the notching (a clear indication of hub doubling), rounded secondary images and how the deeper hubbing shifts consistently in one direction from the lighter hubbing.

On to CLASS V

All doubled die illustrations are by Jason Cuvelier