Reeding vs. no reeding varieties (foreign only)

Concentric lathe lines (ES Nov/Dec 2003)

-

- Various years and denominations

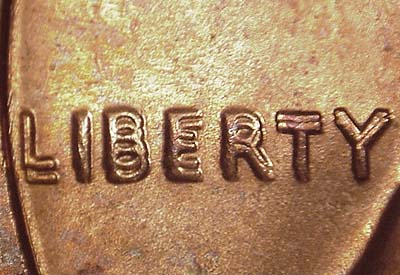

- Common on the 1996-D Lincoln cent

- Various years and denominations

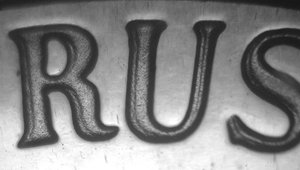

Rusted dies (CW 12/1/08)

Excessively deep rim gutter

-

- 1991 cents

Rockwell test mark left in die (hemispherical bump seen on coin) (ES July/Aug 2006)

Vickers test mark left in die (pyramidal bump) (CW 5/15/17)

Collar manufacturing errors

-

- Wide collar (ES Nov/Dec 2002; CW 5/17/10)

- Created by improper machining or improperly machined broach

- Created by use of wrong broach

- Improper use of correct broach

- Widening due to wear

- Widening due to 3 or more vertical collar cracks and associated expansion (CW 5/17/10)

- Abnormal reeding

- 1921 Morgan dollar with infrequent reeding

- 1924-D Mercury dime with infrequent reeding

- 2015 American Eagle 1/10oz gold bullion coin with narrow reeds (CW 7/13/15)

- Low, narrow reeds caused by truncation of ridges on collar face (ES March/April 2010; CW 1/25/10, 4/16/12)

- 1964-D 25c

- 2008-P New Mexico 25c

- COIN WORLD SPECIAL: article posted HERE

- Wide collar (ES Nov/Dec 2002; CW 5/17/10)

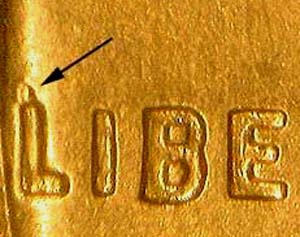

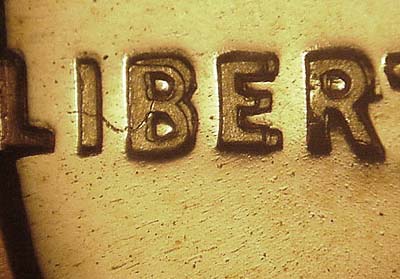

Hub retouching

-

- Channeling: Retouching of design element on master and/or working hubs (1920s to 1940s) (CW 7/23/12)

- Re-engraved master hub (CW 1/1/24)

- Channeling: Retouching of design element on master and/or working hubs (1920s to 1940s) (CW 7/23/12)

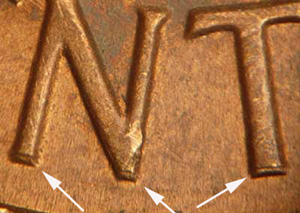

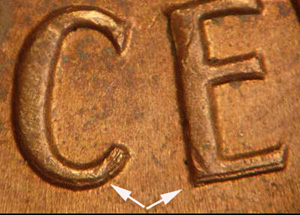

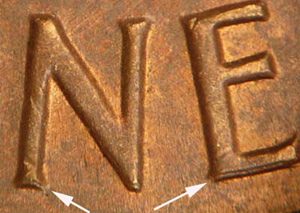

Die retouching (CW 5/30/16, 9/30/19)

-

- Re-engraved designer’s initials “AW” on 1944-D half dollar (CW 2/2/04, 2/16/04, 3/1/04)

- Re-engraved tail feathers on business-strike 1957-D quarter

- Re-engraved front of Lincoln’s coat (1953 proof cent)

- Re-engraved queue on 1952 – 1954 proof nickels

- 1938 proof nickels with re-engraved letters and design details (ES Jan/Feb 2009)

- Retouching of the 1944 date on the Lincoln cent master die

- Retouching of the date on 1946-S Lincoln cent working dies

- Re-engraved designer’s initials “AW” on 1944-D half dollar (CW 2/2/04, 2/16/04, 3/1/04)

Die damage (ES Nov/Dec 2004, Jan/Feb 2003; CW 5/21/12)

-

- Die dents (ES Nov/Dec 2004, July/August 2005, Nov/Dec 2005; CW 9/15/03, 12/22/14, 3/28/22, 7/31/23)

- Die scrapes (CW 4/23/07)

- Accidental die scratches

- Die gouges

- Impact scars

- Accidental die abrasion (CW 9/8/14, 12/16/19)

- Intentional die abrasion (“die polishing”) (CW 3/29/10, 5/31/10, 9/8/14, 3/20/23)

- Heavy die scratches

- Thinning and loss of design elements

- Two Feather Indian Head Nickel (various dates)

- 3-legged Indian Head Nickel (1937-D)

- 3 ½ legged Indian Nickel (1936-D)

- Abrasion affecting entire die face

- Localized abrasion

- Defects related to die polishing

- Over-polished proof and Special Mint Set dies (CW 2/21/11)

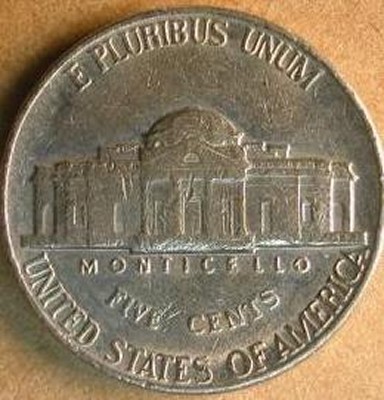

- Trails and Wavy Steps (ES July/Aug 2006, Sept/Oct 2006, Nov/Dec 2006, Jan/Feb 2011; CW 3/8/10)

- Localized removal of field from proof polishing (CW 2/14/2011)

- COIN WORLD SPECIAL: article posted HERE

- Die attrition errors (ES May/June 2003, March/April 2005, March/April 2009; CW 1/4/10, 12/24/12, 4/14/14, 11/4/19, 7/3/23, 10/16/23)

- Other forms of peripheral die damage (ES March/April 2005; CW 8/9/21, 3/14/22)

- Catastrophic die damage (ES March/April 2002; CW 9/15/03, 9/12/11, 9/19/11, 5/20/13, 10/27/14, 6/19/17)

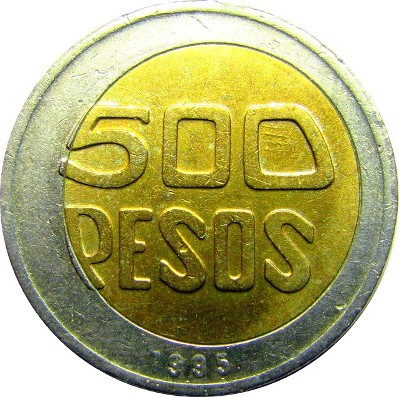

- Cancelled or defaced dies (foreign only) (CW 5/8/17, 12/31/18)

- 1994 Hong Kong bimetallic 10 dollars

- Egypt 25 piastres struck by defaced 50 piastres dies (CW 5/12/14)

- 1966 Bolivia 10 centavos struck by pair of canceled dies (CW 5/8/17)

- Chilean test dies with concentric cancellation pattern struck over struck foreign core (CW 5/8/17)

- Rockwell test mark in die (CW 5/15/17)

- Vickers test mark in die (CW 5/15/17)

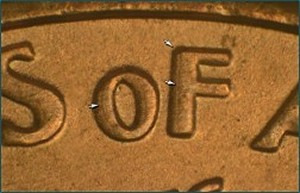

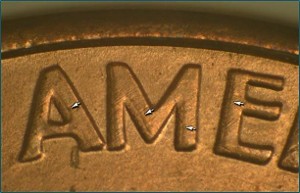

- Die rings (tiny rings, semicircles, crescents, and spirals) (CW 2/20/17, 1/18/21, 6/13/22)

-

- Centrally-located

- Offset

-

- Collar damage (ES March/April 2010; CW 1/25/10, 4/16/12, 6/17/19)

- Horizontal abrasion (CW 1/25/10, 4/16/12)

- Vertical abrasion (CW 6/17/19)

Hubbed-In debris (CW 5/27/13)

Deformed collar (CW 12/18/20)

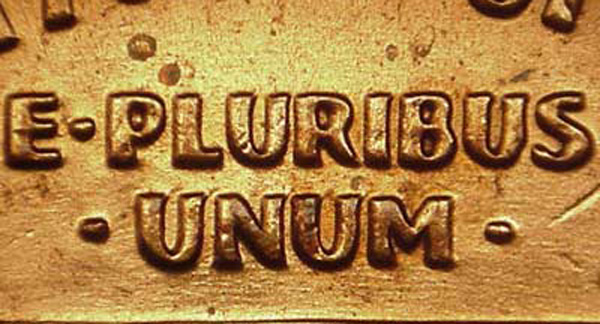

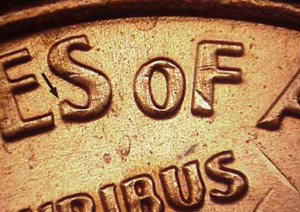

Clashed dies (ES March/April 2002; CW 3/22/10, 4/30/12)

-

- Clash marks

- Multiple clash marks (CW 6/25/12, 11/11/19)

- Clash marks

- Raised clash marks (CW 8/11/14)

- Double clash with reciprocal counterclash (Type 1) (ES Nov/Dec 2004; CW 12/13/10, 7/29/19)

- Misaligned die clashes (ES May/June 2004, July/August 2004; CW 6/25/12)

- Horizontally misaligned die clash

- Vertically misaligned (tilted) die clash (CW 1/3/11, 5/9/11)

- COIN WORLD SPECIAL: article posted HERE

- Pivoted die clash

- Radically misaligned, rotated, pivoted clashes – produced at installation? (CW 7/12/10, 12/31/12, 5/27/19)

- Co-occurrence with conventional clash (CW 8/17/15)

- Rotated die clash (CW 1/22/18, 6/26/23)

- Combination clashes

- Mule clash errors, e.g. (ES July/August 2002; CW 11/17/08, 8/13/18, 8/20/18, 4/8/19)

- 1864 2c reverse die clashed with Indian cent obverse die

- 1857 1c obverse die clashed with Seated Liberty 50c obverse die

- 1857 1c reverse die clashed with Seated Liberty 25c reverse die

- 1857 1c obverse die clashed with Liberty $20 obverse die

- (For detailed information concerning the 1857 die clashes CLICK HERE)

- 1870 Shield nickel obverse clashed with Indian Head cent obverse

- 1999 cent reverse die clashed with another cent reverse die

- Floating die clash (collision with die fragments) (ES May/June 2002, May/June 2005; CW 7/19/10)

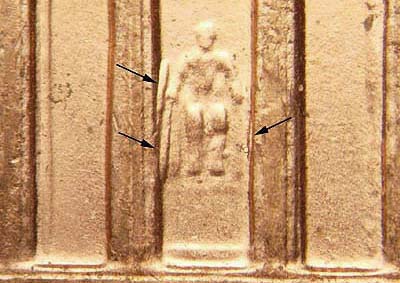

- Superclash (full reciprocal design transfer) (CW 3/22/10, 10/22/18)

- Circumferential clash marks (CW 12/10/18)

- Grease-enhanced clash marks (CW 10/16/17)

- Associated with weak strikes (CW 12/2/19)

- Clashed die progressions (CW 5/15/23)

Collar clash (CW 6/11/07, 2/24/22)

-

- Hammer die

- Anvil die

- Inverted die setup (uncommon)

- Traditional die setup (extremely rare) (CW 10/30/23, 12/18/23)

- Floating collar clash (CW 4/17/17)

- Misaligned collar clash (CW 2/13/23)

Die damage with design transfer

-

- Floating die clash (ES May/June 2002, May/June 2005; CW 7/19/10)

- Exogenous floating die clash (CW 6/20/22)

- Floating (Type 2) counterclash (ES May/June 2002, July/August 2002, Sept/Oct 2002, Jan/Feb 2009, Sept/Oct 2011; CW 9/29/08, 12/13/10, 4/9/12, 4/21/14, 6/8/15, 4/23/18, 2/21/22, 12/19/22, 2/20/23)

- COIN WORLD SPECIAL: article posted HERE

- Miscellaneous and unexplained forms of design transfer/duplication

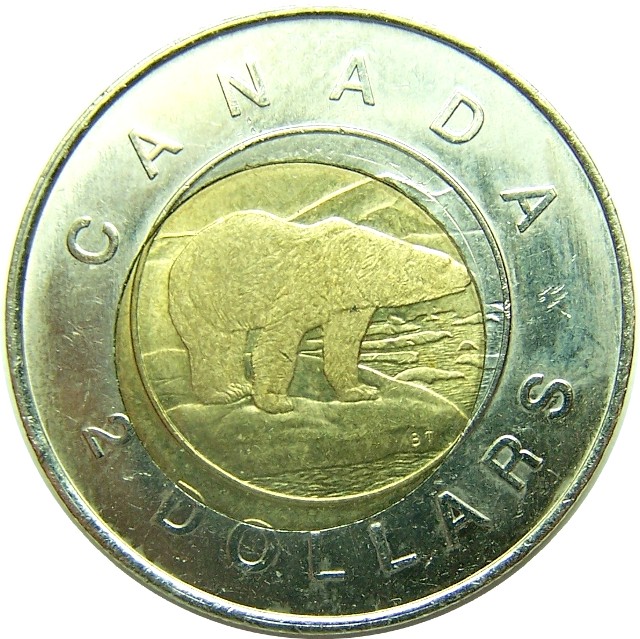

- Some presumed Canadian counterclashes may prove to be something else

- Floating die clash (ES May/June 2002, May/June 2005; CW 7/19/10)

Die deterioration/deformation errors

-

- Exaggerated conventional die wear (CW 12/27/21)

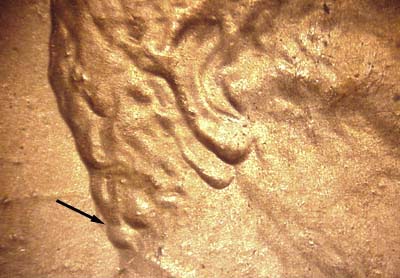

- Radial flow lines

- Concentric flow lines (uncommon)

- Parallel flow lines (promoted by pre-existing trails)

- Orange peel texture

- Design-devouring die wear (thinned letters and numbers) (CW 10/28/13, 2/22/16, 8/23/21)

- Die deterioration doubling

- Raised doubling

- Incuse (CW 2/4/08)

- “Blebs” or “patches” (die erosion pits) (ES July/Aug 1998; CW 7/21/03)

- Discrete lumps (CW 4/27/20)

- Progressive, indirect design transfer (“internal metal displacement phenomenon”, “ghosting”) (CW 6/7/10, 8/17/20)

- Common in 1946-S and 1948-S cents

- Surface-level die deformation errors (ES July/Aug 2001, Nov/Dec 2001; CW 9/17/12) (premature, localized, exaggerated, and peculiar patterns of deformation)

- 1943-S “goiter neck” quarter

- Detail-erasing die wear (2016-P Harper’s Ferry quarter) (CW 2/27/17)

- “Ridge rings”

- On copper-plated zinc cents (CW 2/14/05, 2/28/05)

- On other U.S. denominations (CW 2/15/21)

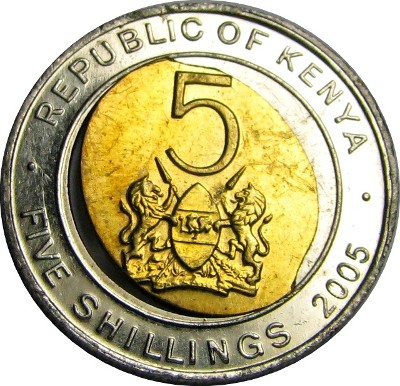

- On world coins (ES Sept/Oct 2006; CW 2/17/14, 11/10/14)

- Design berms (raised outlines) (CW 5/14/18, 11/6/23)

- Die subsidence (sunken die) error (ES July/August 2004, Nov/Dec 2004; CW 6/2/03, 11/29/04, 3/12/12, 2/12/18, 8/14/23)

- e.g., 1924-S – “goiter” cent

- Co-occurring with split dies

- Co-occurring with radial, antipodal die cracks (CW 6/20/11)

- 1988-P nickels with lump on head

- COIN WORLD SPECIAL: article posted HERE

- Massive die collapse in 2003-D dime (ES Nov/Dec 2011; CW 8/29/11)

- Paralleling and flanking die cracks (CW 8/12/13)

- Recurring die subsidence error (CW 4/4/11, 3/31/14)

- Linear die subsidence errors (CW 8/12/13)

- Thermal warping (CW 5/29/23)

- Design creep

- Reverse (hammer) 2014-P nickel die (CW 4/20/15)

- In fractional Euro coins

- Peripheral die expansion and erosion (CW 8/13/12, 4/13/15)

- “Starburst” pattern of radial streaks (cause uncertain) (CW 8/15/05, 11/7/05)

- Reciprocally deformed, convex-concave dies

- Centrally-located deformation; 2001-P 50c) (ES Sept/Oct 2008; CW 1/19/15)

- Peripherally-located deformation; India 2 rupees (CW 1/19/15)

- Exaggerated conventional die wear (CW 12/27/21)

-

- Cuds (corner die breaks) (CW 10/17/11, 10/4/21)

- Irregular cuds

- Ovoid cuds

- Crescentic cuds (ES March/April 2005; CW 2/15/16)

- Circumferential cuds (ES March/April 2005; CW 2/15/16)

- Rim-to-rim cud (ES May/June 2003, CW 12/24/18)

- Elongate Cuds (CW 12/8/14, 12/21/20, 7/31/23)

- On off-center or broadstruck coins (CW 9/12/11)

- Deep vs. shallow die breaks (CW 6/2/20)

- Retained Cuds (ES Jan/Feb 2006; CW 4/17/06, 7/24/06, 1/24/11)

- COIN WORLD SPECIAL: article posted HERE

- Anvil die (diagnosis often in doubt)

- Hammer die (doubtful) (CW 8/8/13)

- With vertical displacement

- With horizontal offset

- With lateral spread

- Outthrust (protrudes beyond die face) (CW 3/11/19)

- Hammer die

- Anvil die

- Cuds (corner die breaks) (CW 10/17/11, 10/4/21)

- Interior (internal) die breaks (ES May/June 2003; CW 10/25/10, 11/5/18, 8/14/23)

- Connected to die cracks or splits

- Freestanding (ES May/June 2005)

- Retained interior die breaks (ES July/August 2004)

- Rim cuds (CW 5/3/21)

- Die chips (CW 6/14/19, 7/8/19)

- On raised die features (CW 2/28/22)

- Catastrophic die failure (ES May/June 2007; CW 5/20/13, 2/27/23, 6/19/23)

- Spontaneous breaks

- Breaks produced by impacts

- Textured and dimpled cuds (CW 10/17/11, 10/12/20)

- Cryptic cuds (CW 4/17/23)

Die exfoliation errors (CW 10/19/20)

Collar breaks (collar cuds) (ES May/June 2008; CW 11/22/10, 5/17/10, 11/22/10, 12/19/16)

-

- Complete collar break (abrupt loss of entire arc segment)

- Irregular collar break

- Chipped collar

- Vertical collar crack

- Retained collar break

- Rotating collar break (ES July/August 2003; CW 1/6/03, 12/12/16, 4/20/20, 12/28/20)

- Bilateral split collar

- On off-center strikes (CW 9/9/19)

- Catastrophic collar failure (CW 7/17/23)

Die cracks (CW 4/25/16)

-

- Rim-to-rim

- Arcing rim-to-rim (“pre-cud”) die crack (ES Jan/Feb 2006; CW 2/8/21)

- With lateral spread

- Blind-ended

- Bi-level die cracks (ES July/August 2004)

- Protruding marginal die segments (CW 5/19/14)

- Radial, antipodal die cracks (with centralized subsidence) (ES Sept/Oct 2011; CW 6/20/2011)

- Die Crazing (Crazed Die)

- Shattered dies (ES Jan/Feb 2006, May/June 2007; CW 4/7/08, 9/17/18, 4/6/20)

- Broas Pie Baker Store Card Token of 1863

- Two or more splits in die

- Numerous wide, intersecting, raised die cracks

- Numerous intersecting bi-level die cracks

- Various combinations of brittle fracture

- In response to impacts (CW 6/19/17)

- Impact-Induced Die Cracks (CW 6/19/17)

Split dies (ES Jan/Feb 2006; CW 6/2/03, 4/10/06, 4/17/06, 6/20/2011, 5/11/15, 9/17/18, 4/26/21, 4/18/22, 7/18/22)

-

- Median (bisecting) split die

- Asymmetrical split die (CW 7/31/23)

- False split (bilateral, radial, antipodal die cracks) (ES Sept/Oct 2011; CW 6/20/2011)

Photographs are courtesy of Coppercoins.

Photographs are courtesy of Coppercoins.