PART IV. Die Errors:

Vertically Misaligned Die Error (Tilted Die Error)

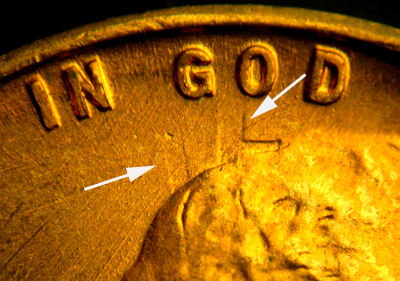

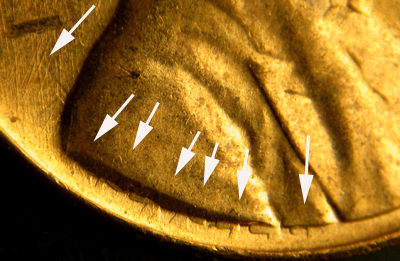

Definition: A die or the entire die assembly can fall out of adjustment so that the two opposing die faces are no longer parallel. The tilted die will strike the planchet at an angle. One pole will be very well struck while the opposite pole will show little or no design. The pole that is well struck will show a very strong design rim and often finning of the rim. The opposite pole will retain the original proto-rim of the unstruck planchet. Extreme tilted die errors usually show a horizontal misalignment as well. That’s because when a die tilts down, it also tilts in.

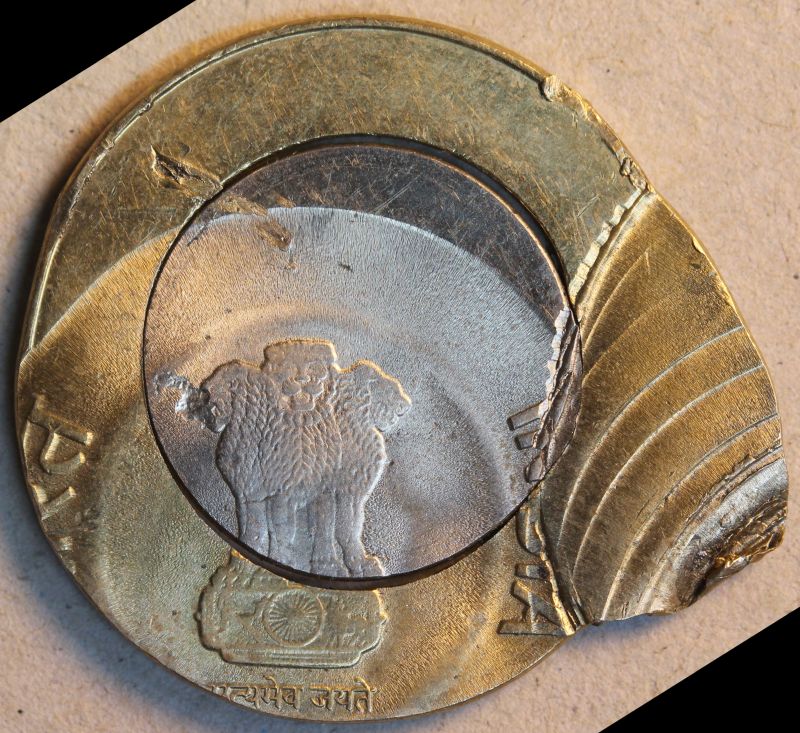

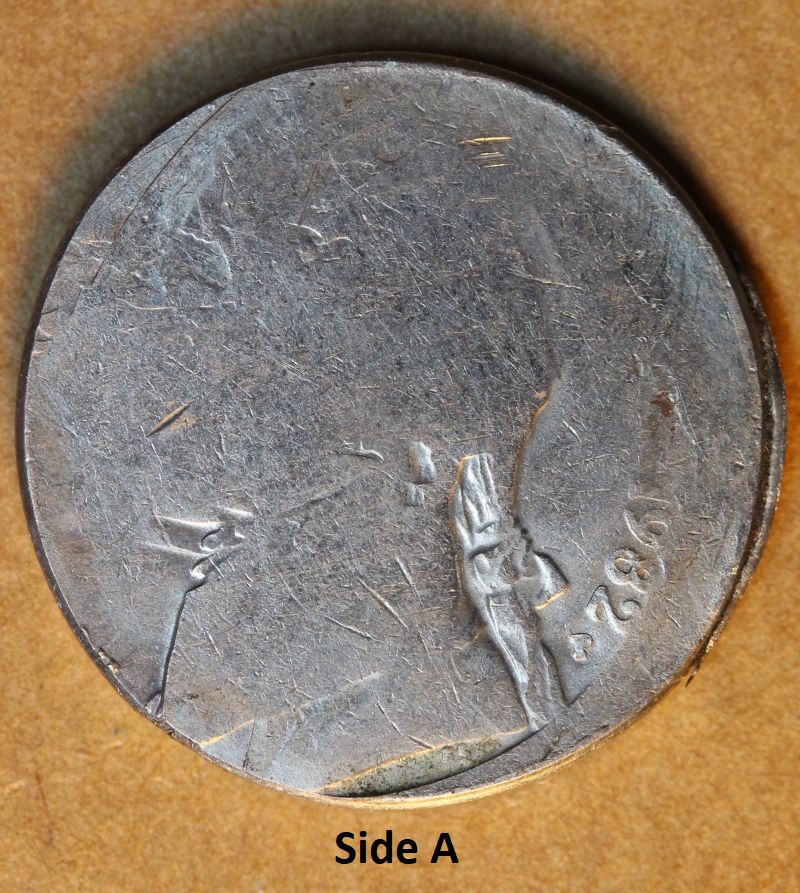

This 1972-D half dollar shows a combination die alignment error. The vertical misalignment co-occurs with a 90 degree rotated die error.