PART II. Die Varieties:

Overdates

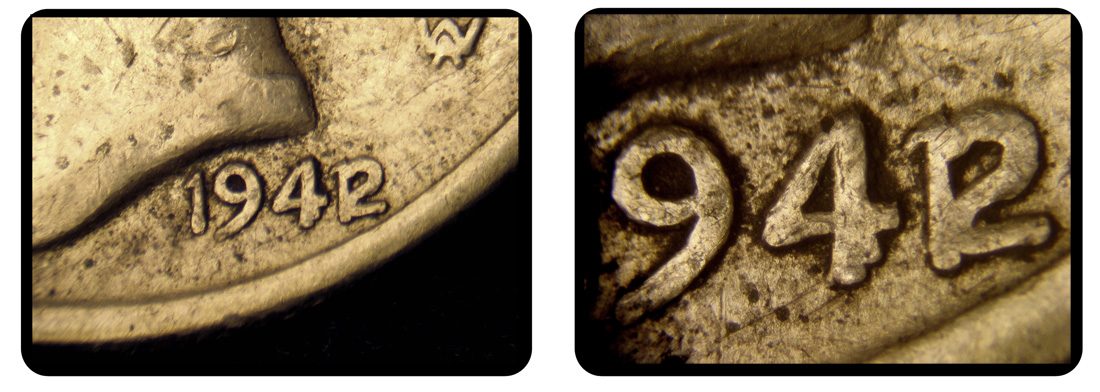

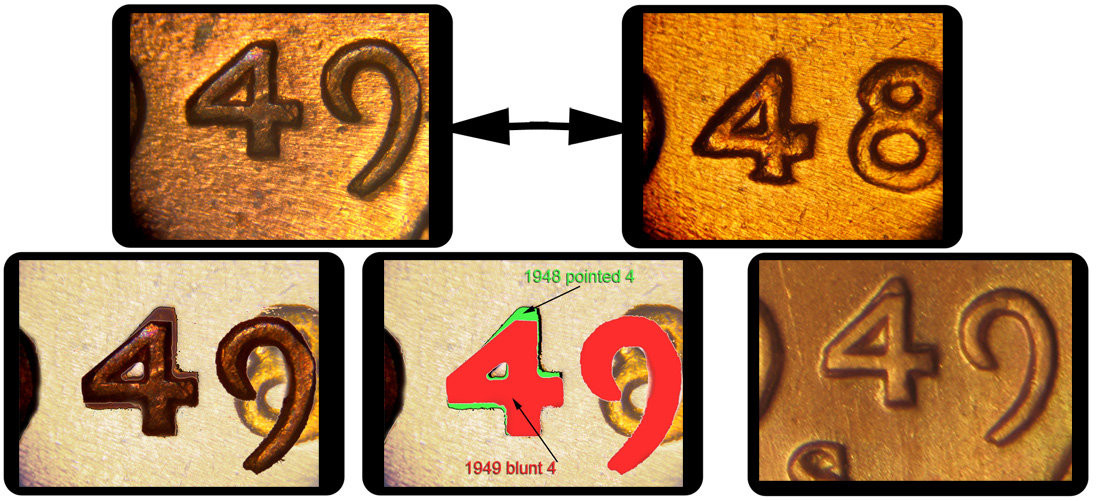

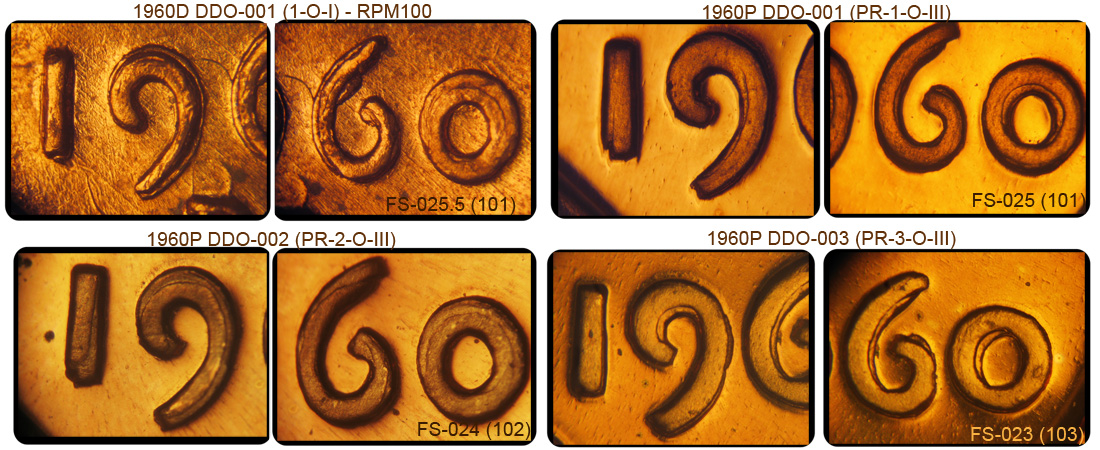

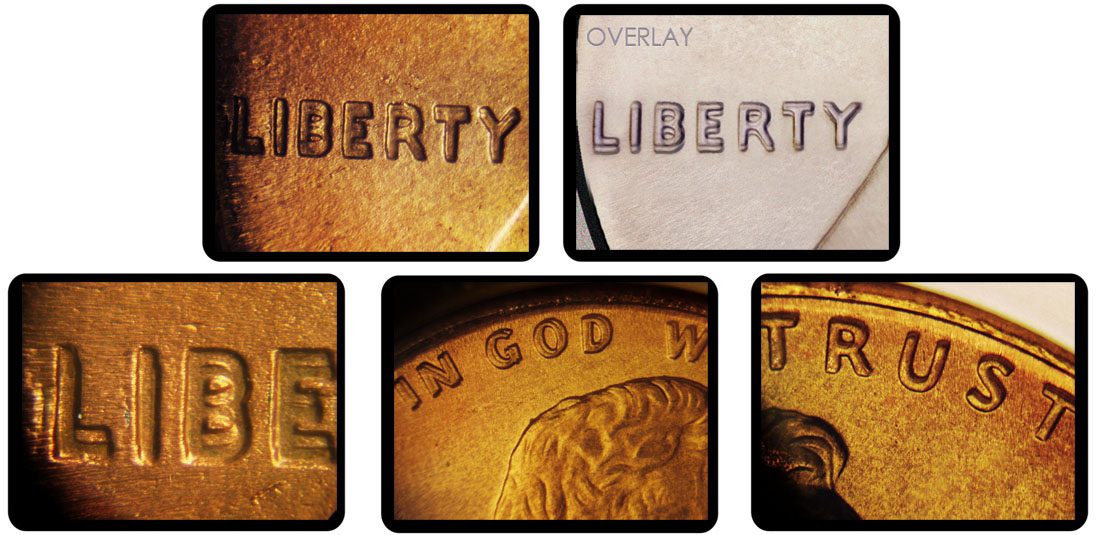

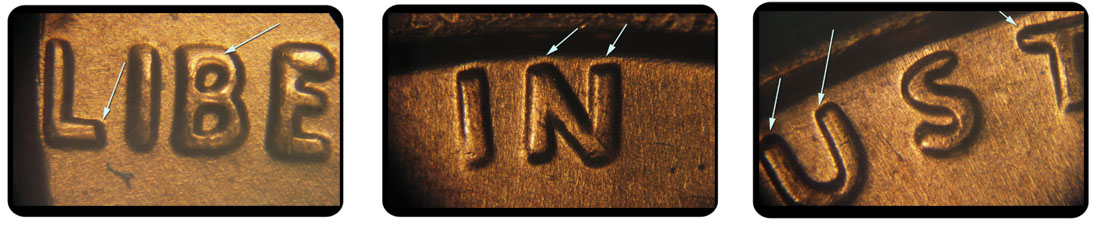

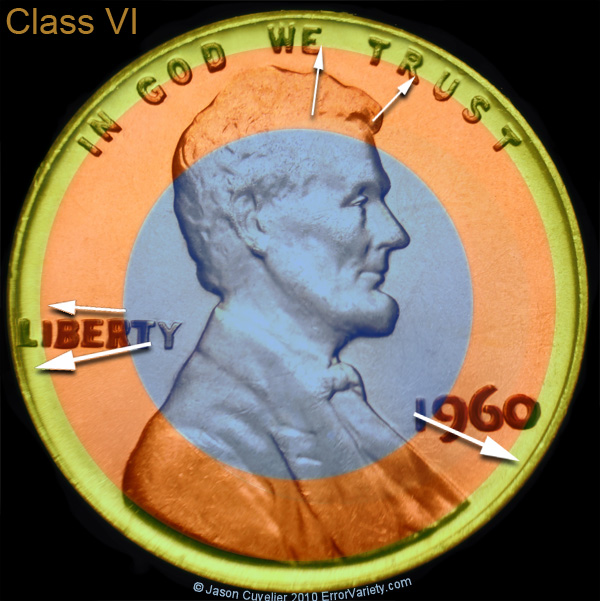

Definition: An overdate is a modification made to a working hub that involves two different numerals being punched or engraved into the same spot. One or more digits may be affected. Overdates sometimes represent an attempt to correct a mistake when the wrong punch was initially used to punch in a digit. At other times it represents an expedient measure. Dies left over from the previous year may simply have one or several digits repunched so that the die can be used in the current year. The relevant area of the die face is often abraded so that the prominence of the original date is reduced.

Overdates are closely related to re-punched dates. However, a re-punched date doesn’t involve the superimposition of one digit over a different digit. Repunched dates simply involve the repunching of the same digit or digits.

Overdates should not be confused with Class III doubled dies (design hub doubling). Although the outcome looks similar, the nature of the variety is entirely different.

Overdates ceased being a possibility for U.S. coins in 1909 when the mint began placing an engraved date on the master die.

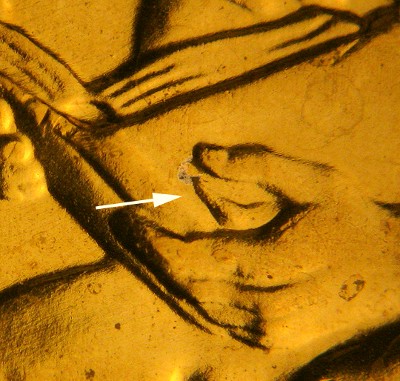

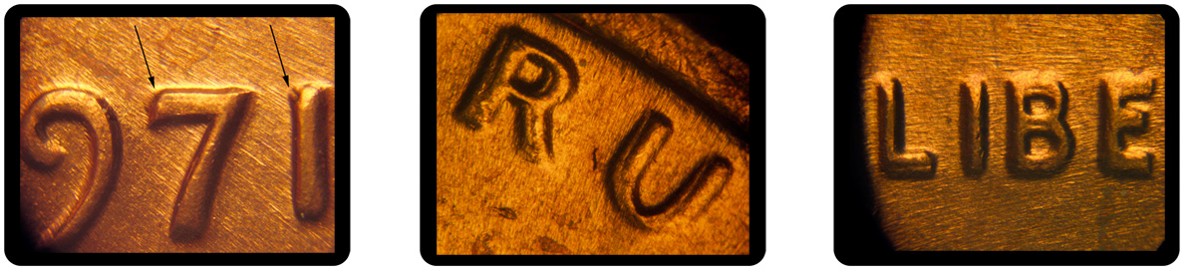

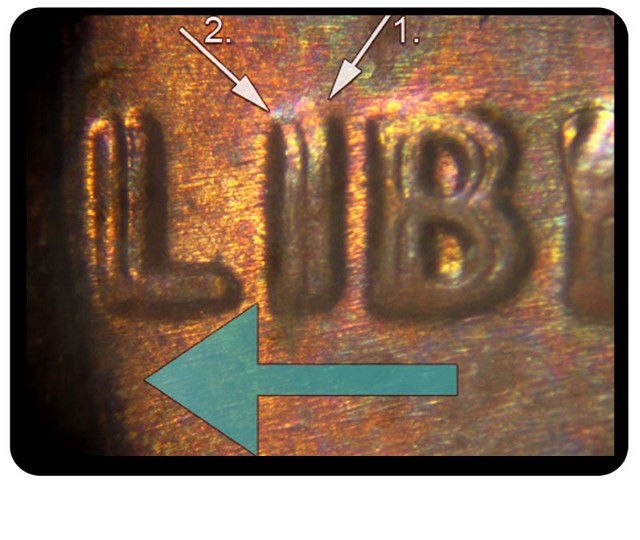

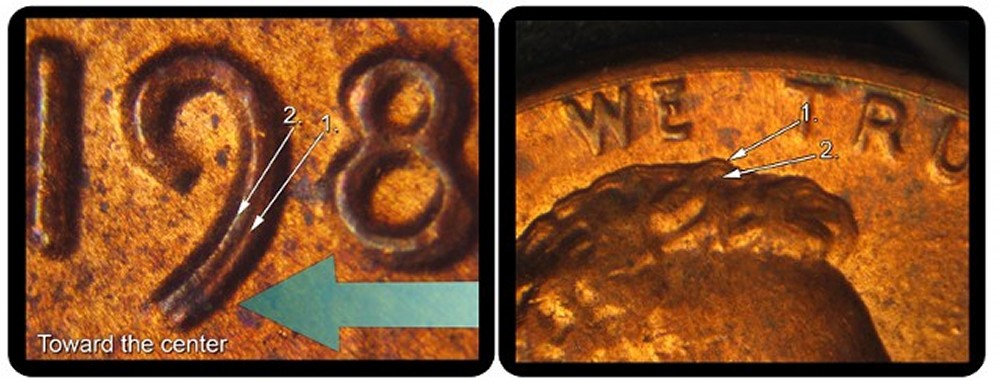

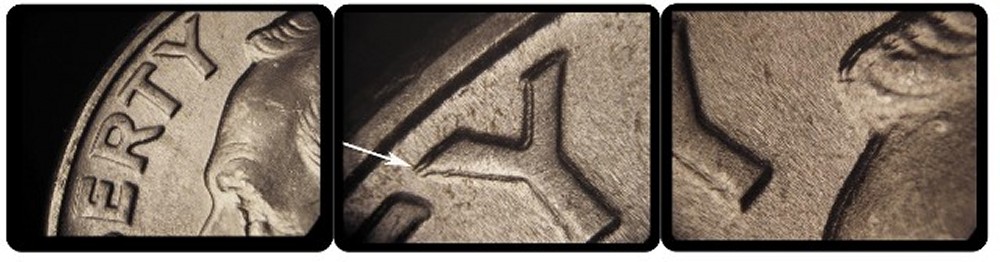

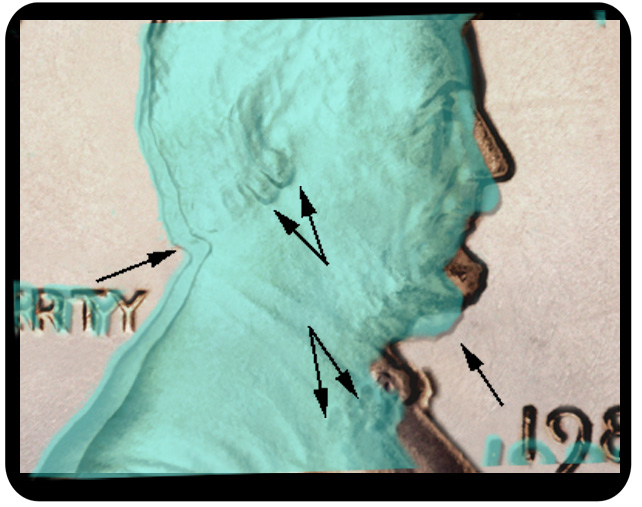

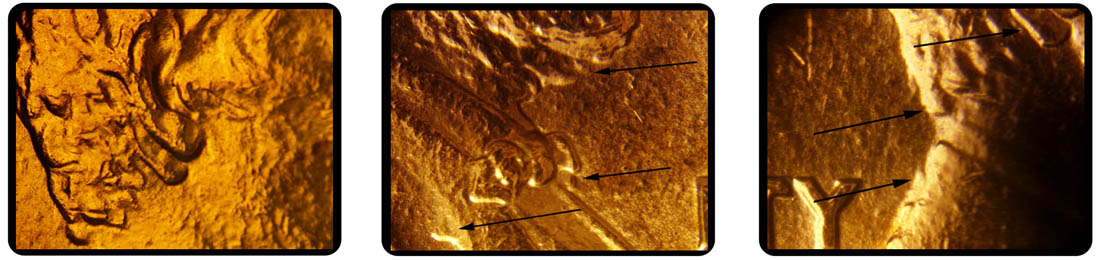

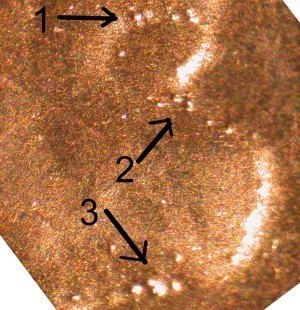

The image below shows an 1892 Peruvian 1/2 dino, with a repunched 9 over an underlying 8.