PART V. Planchet Errors

Plating blisters

Definition: This error type occurs only on copper-plated zinc cents from 1982 to the present. Blisters form during the strike when expanding gas pushes up the copper plating from heat and pressure. A weak bond between the copper plating and the zinc core is a necessary prerequisite as are contaminants within or under the plating.

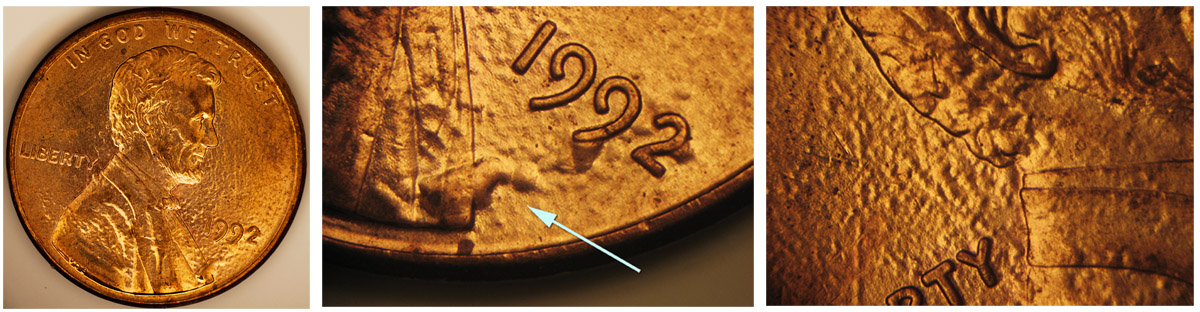

Below is a 1992 Lincoln cent with circular plating blisters. The largest blister is oblong and irregular, it runs through Lincoln’s coat into the field and below the date.

Illustration by J. Cuvelier

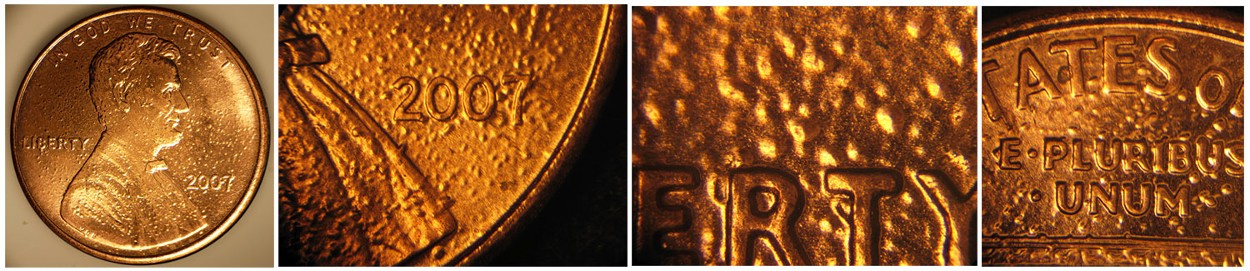

A 2007 Lincoln cent with circular plating blisters on both the obverse and reverse.

Illustration by J. Cuvelier

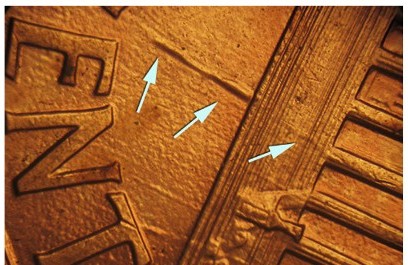

Three Lincoln cents (1984, 1996-D and 1985) with linear plating blisters. The 1984 has some circular blisters mixed in.

Illustration by J. Cuvelier

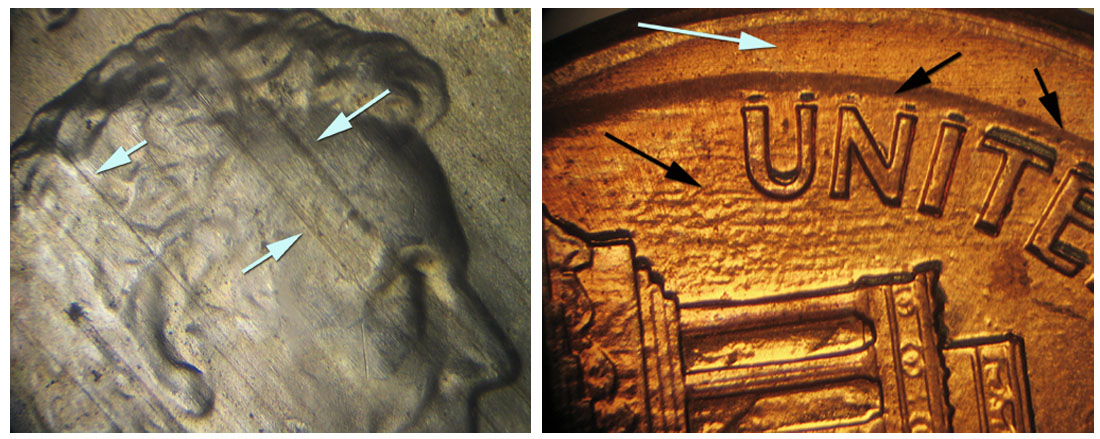

Below to the left are planchet striations on the surface of an unplated Lincoln cent. Below to the right is an off-center cent that shows the matte surface of the planchet free of blisters. The struck portions of the coin show both circular and linear plating blisters. The linear blisters run parallel to the planchet striations present on the unstruck portions.

Illustration by J. Cuvelier

For comparison purposes, the upper image is a 1995 Lincoln cent reverse with a long linear plating blister; below and to the right, is a 1986-D Lincoln cent that shows a solid blister from corrosion on the mintmark. More specifically, it shows a dome of subsurface corrosion that has ruptured or that began as a slight tear in the copper plating. It should not be confused with a normal plating blister.

Plating blisters are hollow. They look similar to, but should not be confused with, solid blisters pushed up by subsurface corrosion. Solid blisters are pushed up by gas under the expanding metal. Zinc corrosion (“zinc rot”) can be induced by contaminants trapped between the zinc core and the copper plating. A more common cause of zinc rot is the presence of a small perforation or tear in the copper plating. This allows oxygen and reactive compounds to reach the zinc core.

Illustration of 1995 by J. Cuvelier

Image of 1986 by Richard Cooper