PART V. Planchet Errors:

Annealing Errors:

Improper Annealing:

Definition: For decades error collectors have puzzled over copper-nickel and Cu-Ni clad coins struck on planchets with a layer of copper on the surface. In times past, these errors were called “copper wash” and “sintered plating” errors. The 1962 nickel shown below is a typical example. It has a thick layer of peeling copper on the right side of the obverse face. The rest of the obverse face and all of the reverse face is black. Copper, red, black, brown, and gray are colors typically found in these errors. Coverage can be complete or incomplete. The copper can range from a slight tinge to a thick coating.

In recent years, eyewitness testimony has convincingly pointed to annealing as the specific step in the planchet preparation responsible for the surface copper. In light of this testimony, these errors are now generally labeled “improper annealing” errors by the major grading services.

In 2010 Mike Diamond contacted US Mint officials with convincing evidence which in the end supported his hypothesis that copper and nickel atoms in the 75% Cu / 25% Ni alloy were migrating and segregating themselves into layers of relative purity. In response to an inquiry first made to Tom Jurkowsky, the Mint’s Director of Public Affairs, an answer came henceforth. Michael White, a spokesman for the Office of Public Affairs, consulted with the Mint’s technical staff who reported a mechanism very similar to the first scenario Mike Diamond laid out. The atoms are migrating to the surface and rearranging themselves into uniform layers. The proximate cause, according to Mr. White, is prolonged exposure to heat, a failure to maintain an oxygen-depleted atmosphere in the annealing oven, or a combination of both. Here is Mr. White’s verbatim explanation:

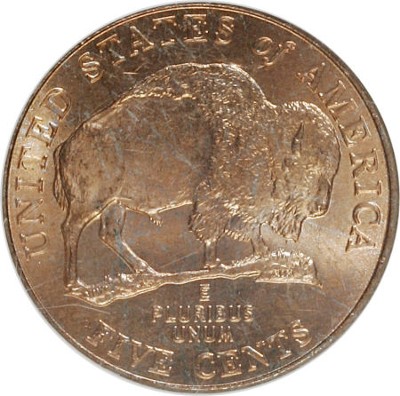

Another example of improper annealed planchet is the 2005-D Jefferson nickel with Bison reverse.

Images are courtesy of Heritage Auctions.